Metal powder promises new alternative to fossil fuels : Metal powders could be a more handy alternative to fossil fuels than biofuels or hydrogen, researchers have suggested.

Tiny metal particles about the size of a fine flour grain could be used to power the so-called external combustion engines that use heat from an outside source.

Such engines, known from traditional coal-fired steam locomotives, are currently used in most power stations. The technology, in principle, is the same as used in fireworks and is also commonly employed in solid-fuel boosters that propel rockets to space.

However, the range of applications could be much wider, a team of scientists from Canada’s McGill University and the European Space Agency believes, potentially opening new ways for reducing greenhouse gas emissions.

“Biofuels can be part of the solution, but won’t be able to satisfy all the demand; hydrogen requires big, heavy fuel tanks and is explosive, and batteries are too bulky and don’t store enough energy for many applications,” McGill University Professor Jeffrey Bergthorson explained the benefits of the technology described in the latest issue of the journal Applied Energy.

“Using metal powders as recyclable fuels that store clean primary energy for later use is a very promising alternative solution.”

The major advantage of metal powders, the team said, is the fact that upon burning, they create stable non-toxic solid oxides that can be easily collected and recycled’ unlike CO2 resulting from burning of fossil fuels.

“The energy and power densities of the proposed metal-fuelled heat engines are predicted to be close to current fossil-fuelled internal combustion engines, making them an attractive technology for a future low-carbon society,” the researchers wrote in the article.

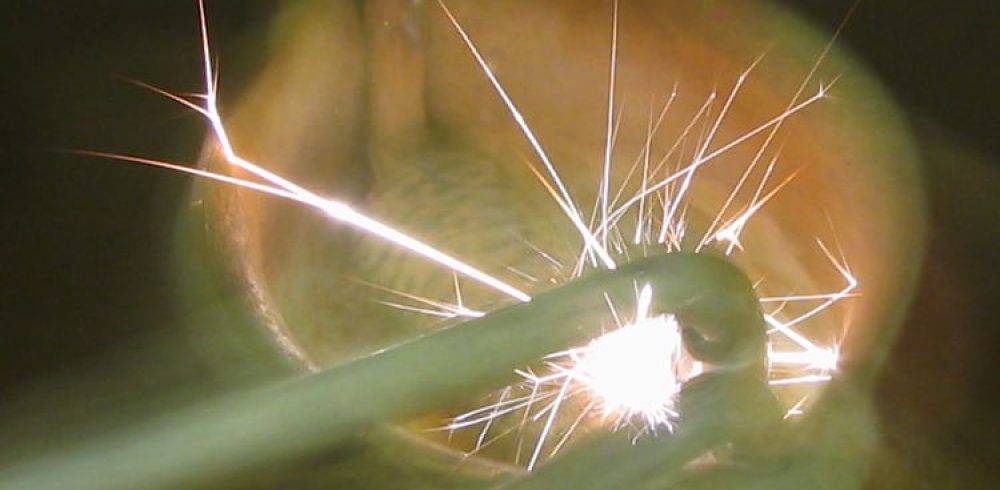

The experiment was conducted using a custom-built burner in which the metal particles were suspended in air.

The team said that iron powder could be particularly convenient as tonnes of iron powders are produced annually for the metallurgy, chemical and electronic industries. Moreover, methods and technologies for iron recycling are already well developed. Although traditional methods of iron production rely on coal and therefore result in CO2 emissions, the scientists said that technology for cleaner iron production already exists.

“We are very interested in this technology because it opens the door to new propulsion systems that can be used in space and on earth, said David Jarvis, head of strategic and emerging technologies at the European Space Agency. The shift away from fossil fuels for vehicle propulsion is a clear trend for the future. While not perfected and commercialised today, the use of low-cost metallic fuels, like iron powder, is a worthy alternative to petrol and diesel fuels

The team will now focus on building a prototype iron powder burner that could be coupled with a heat engine to demonstrate that it is possible to use metal powders in combustion engine with almost zero emissions.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News