Stratasys (NASDAQ: SSYS) has announced a series of innovations across its FDM, SAF, P3™ DLP, and software platforms, expanding material choices, improving throughput, and introducing new capabilities to help manufacturers streamline additive production.

“By expanding our materials portfolio, accelerating print speeds, and introducing smarter software tools, we’re helping customers tackle challenging applications more efficiently,” said Rich Garrity, Chief Business Unit Officer. “These updates reflect our ongoing commitment to driving innovation and operational excellence across aerospace, automotive, industrial, and consumer markets.”

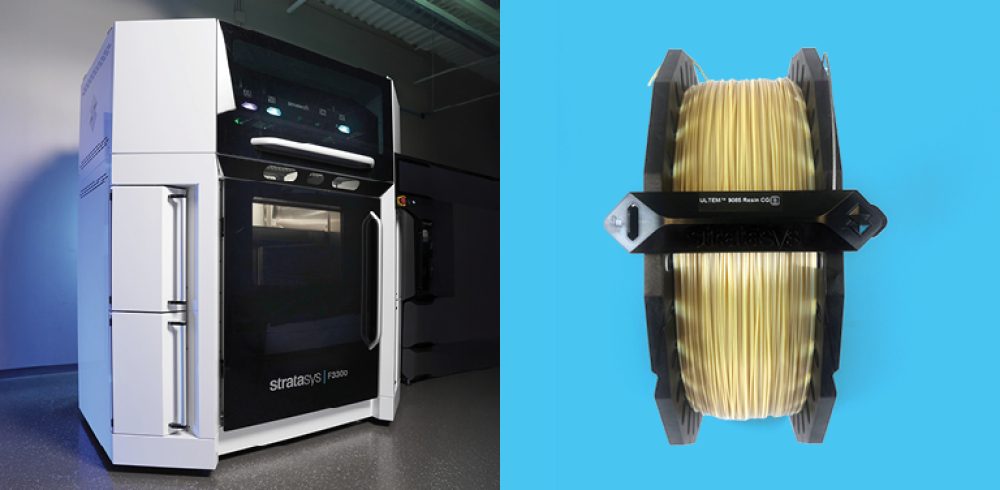

The innovations have been applied across several key technology areas. Within Fused Deposition Modeling (FDM), the F900 printer now includes a software-enabled print mode called CoatReady™, designed to improve surface quality when printing with ULTEM™ 9085 resin. It delivers smoother surfaces that require less sanding and priming before painting – reducing manual finishing time, accelerating production, and increasing overall throughput. Meanwhile, the introduction of ULTEM™ 9085 Filament CG for the F3300 printer will support aerospace-grade performance with full traceability and tighter diameter tolerance for strong, repeatable parts.

Other FDM-focused innovations include Nylon 12CF T40 Tip, a new specialized tip for the Fortus 450mc, that nearly doubles build speed for large, high- strength parts with a 0.020-inch slice thickness, ideal for bulky solid components. This capability will be available with the software update of November 18.

The New ULTEM™ 9085 resin in Aircraft Gray and ASA Black are now available as XTEND 250 Spools for the Fortus FDC. These additional material options allow manufacturers to produce larger, stronger parts – benefiting from the FDC’s uninterrupted print times and reduced moisture-related defects. Another update is the ABS Fortus® PLUS TrueRefill™ that provides sustainable, cost-effective filament refill solution for ABS Black, ABS Ivory, and SR-35, cutting material costs by over 35% and packaging consumption by more than 30%.

The Stratasys Stereolithography (SLA) and Selective Absorption Fusion (SAF) technologies have also seen important advancements. For SLA, new LayerControl+™, implemented through Titanium™ software, automatically adjusts layer delay times on the Neo800+ SLA printer to manage thermal variations that can cause costly build failures or surface defects. This predictive control reduces surface defects and build failures while optimizing print speed, as well as improve part quality, and overall reliability. Meanwhile, enhanced accuracy mode (EAM) for SAF™ PP on H350™ will result in optimized thermal management that improves dimensional accuracy, reduces warp, and delivers consistent quality across larger builds. This advancement sets a new benchmark for polypropylene in powder bed fusion (PBF) technology, further solidifying SAF™ polypropylene’s position in automotive, industrial, and machine component applications.

Finally, new technical capability will extend the performance and processing of Stratasys P3 DLP. Ultracur3D® RG 3280 by Forward AM is a ceramic-filled material validated for Origin printers can produce 3D printing mold tools, extrusion dies, and vacuum forming tools for spare part production, small batches or prototyping. With its high stiffness (~10 GPa) and heat deflection above 280°C it withstands the high temperature and pressures of the molding process. The Origin Accessories portfolio has also been expanded, with new tools that simplify part handling, controlled curing, and improved part transparency, enhancing safety and efficiency in production workflows.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News