Accelerate Design Exploration for High-Performance Part Engineering – Cognitive Design Systems (CDS) announces the release of Cognitive Design 2.0, the latest version of its AI-powered engineering platform, featuring the groundbreaking Design Explorer capability. This milestone propels CDS’s vision forward: enabling engineers to unlock, test, and validate manufacturable high-performance designs at record speed—together, in one collaborative environment.

Transforming Design Exploration from Bottleneck to Enabler in Modern Engineering

Across industries such as aerospace, automotive, and defense, engineering teams face mounting pressure in innovative programs to deliver lighter, stronger, and more sustainable parts while reducing costs and time-to-market. In this context, where engineers are required to develop concepts from the ground up, the absence of an exploitable design history often hinders their ability to effectively identify tradeoffs that meet requirements (with the perfect performance – manufacturability-cost balance).

These challenges intensify with frequent system-level changes and evolving specifications. As programs advance and product complexity rises, engineers must continually adjust to updates in boundary conditions, load cases, and space constraints – often triggering costly rework and manual redesign. The impact is clear: fragmented iteration cycles, delayed decisions, and lost opportunities for optimization.

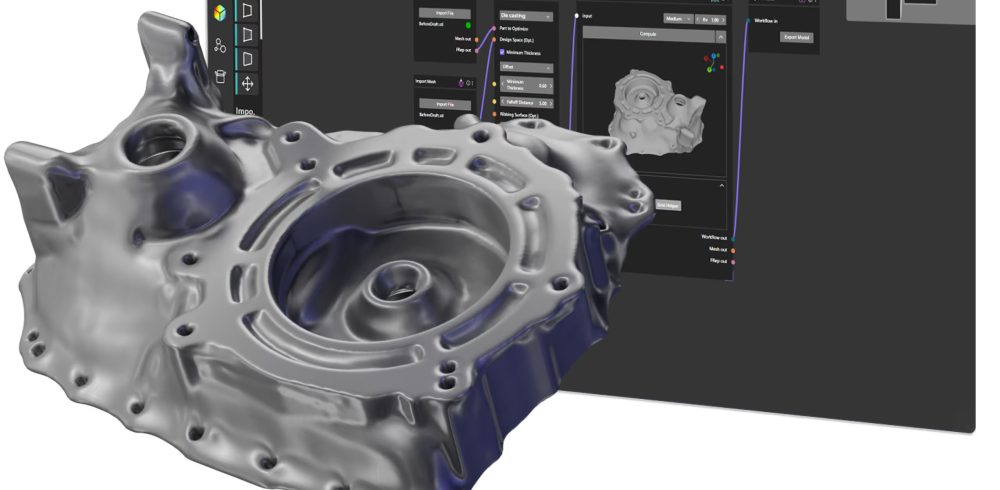

Cognitive Design 2.0 directly addresses this growing complexity by uniting design generation, evaluation, and manufacturability validation into one integrated environment, empowering engineers to always make data-driven decisions with confidence and agility.

Cognitive Design 2.0: The Multi-Disciplinary Design Exploration

The release of Cognitive Design 2.0 represents a major evolution in CDS’s mission to transform the engineering process for teams working on high-performance products where performance and efficiency define success.

At its core, the new version redefines part development by combining:

- Generative design and simulation integration, for rapid exploration of structural part concepts.

- Manufacturing-driven design, embedding process constraints for Additive Manufacturing, Casting, Machining, Molding, and Forging directly into the design workflow.

- Data-driven decision-making, guided by a unified dashboard that compares design iterations across performance, cost, weight, CO₂ emissions, and manufacturability KPIs.

Introducing the Design Explorer: From Iterations to Actionable Insights

The new Design Explorer capability provides a multi-criteria comparative view that centralizes all design iterations, simulations, and cost analyses in a single workspace. Engineers can now:

- Generate and explore high-performance design concepts faster, integrating performance and process constraints from the start.

- Evaluate and compare concepts across quantitative KPIs such as cost, mass, stress, manufacturability, and environmental impact in one unified dashboard.

- Collaborate seamlessly, sharing complete project files including data, context, and summarized dashboards across teams and departments.

“Cognitive Design 2.0 empowers organizations to turn Design Exploration into actionable insights, transforming every engineering workflow into a reusable asset” said Rhushik Matroja, CEO at Cognitive Design Systems.

Cognitive Design 2.0 in Action: A Collaborative Project with Thales Alenia Space

CDS will co-host an upcoming webinar with Thales Alenia Space to illustrate how Cognitive Design 2.0 translates engineering innovation into measurable program impact. The session will showcase how Thales Alenia Space leveraged Design Explorer and reusable, simulation-driven workflows to automate the design of an entire family of antenna reflector tripod supports.

By embedding manufacturing constraints from the start across AM, Casting, Machining, Molding, and Forging, the teams achieved up to 50% shorter engineering lead time and 30% mass reduction per bracket, while maintaining full compliance with mechanical requirements. Registration link here.

About Cognitive Design Systems

Cognitive Design Systems (CDS) is a French software company pioneering advanced design solutions for high-performance product development. Its platform, Cognitive Design, combines generative design, manufacturing-driven design, and collaborative and reusable engineering workflows in one environment. CDS enable leading industrial players to accelerate concept design, optimize manufacturability, and reduce cost – all while maintaining uncompromising performance standards.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News