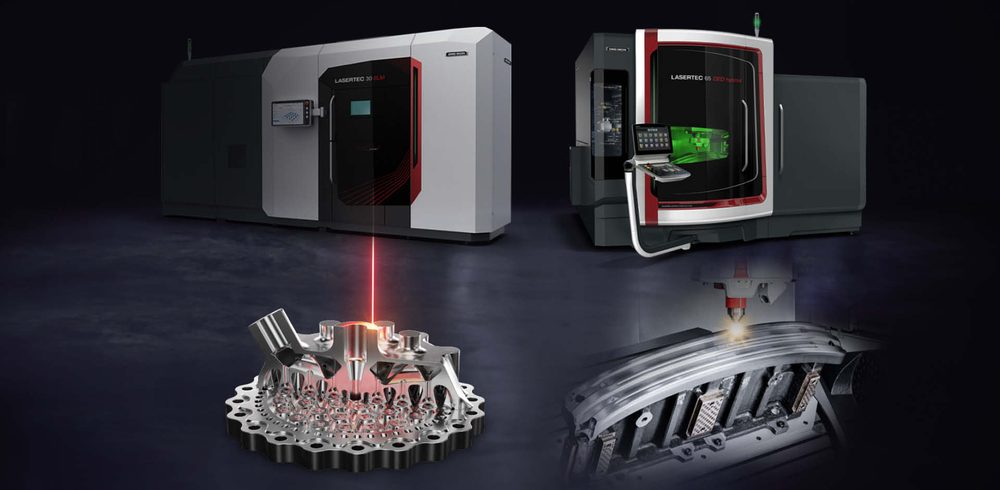

As a full-liner in the additive manufacturing of metallic components, DMG MORI will be demonstrating how these processes can be further optimized at the upcoming Formnext from 18 to 21 November 2025 in Frankfurt. With future-oriented solutions and integrated processes, the machine tool manufacturer ensures that additive manufacturing can also set new standards in series production – both in laser deposition welding on the LASERTEC DED hybrid models and with the powder bed machines of the LASERTEC SLM series. In doing so, DMG MORI underlines its role as an innovation leader and provides an outlook on the role that additive manufacturing will play in the Machining Transformation (MX) in the future.

DMG MORI implements production-ready processing on the LASERTEC DED hybrid machines using a holistic 6-in-1 process. It includes milling, turning and grinding, on the one hand, as well as preheating, additive manufacturing using a powder nozzle and a 3D scan on the other. As part of its Machining Transformation (MX), DMG MORI is thus consistently concentrating on process integration in one clamping. This reduces throughput times because components do not have to be cast, transported and reworked first. The advantages are obvious: The switch between subtractive and additive technologies allows the development of complex geometries and multi-material applications which can be equipped with tailor-made properties, such as better wear or corrosion protection and increased resistance to chemicals. In addition, tool inserts, for example, can be repaired cost-effectively. Additively manufactured components often have a longer service life and reduced maintenance times, so that their availability is significantly increased. At the same time, throughput times are massively shortened.

As the latest part of this process chain, preheating minimizes stress and prevents cracks between the base material and the weld material, which improves mechanical properties. A tool changer-compatible 3D laser scanner enables non-contact and precise quality control through false color imaging. The optional use of blue lasers expands the material spectrum to include highly reflective metals such as copper and allows graded material transitions for highly functional components. At the end of the process chain, there is precise finishing on the same machine. All steps – from preheating to scanning and material application to machining – can be flexibly combined and repeated. This turns a complex multi-stage process into a consistent, highly automated workflow that proves the suitability of hybrid manufacturing for series production in practice.

In the field of powder bed machines, DMG MORI is setting new standards in efficiency, precision and productivity with the LASERTEC 30 SLM 3. Generation. A key innovation is the interchangeable construction container, which eliminates one of the biggest bottlenecks in metallic 3D printing: the long cooling times after construction jobs. Finished containers can be removed without waiting time after completion and replaced by prepared containers – the machine remains productive almost without interruption. Set-up times will also be significantly reduced, as the preparation of the building boards will be carried out externally in the future. This not only eliminates the need for repeated flooding of the chamber with inert gas, but also significantly reduces the consumption of the shielding gas. An integrated lid system also increases safety and preserves the protective atmosphere between two jobs, allowing powder management and material handling under inert gas conditions. In addition, the machine impresses with its robust design. The stable sprue reduces thermal influences, as does the floating process chamber. Active Z-axis compensation stabilizes the layer height, while up to four fully overlapping lasers ensure smooth and productive material processing. With an expanded installation space of 325 × 325 × 400 mm, larger or more components can be manufactured in parallel, making the machine attractive for series production. At Formnext, DMG MORI will also be presenting the new rePLUG FLEX, a simple version of the proven rePLUG powder module. This variant does not require a closed powder circuit within the machine. On the other hand, the material change can be carried out without an additional powder module – an economical solution, especially for materials that are only used on a smaller scale.

The LASERTEC 30 SLM 3. Generation can be operated easily and intuitively thanks to CELOS X with easyAM. Camera monitoring of the powder bed also ensures high component quality while minimizing process interruptions. After each layer, the surface is scanned for anomalies and analyzed. A heat map visualizes possible defects and an evaluation system is used to assign an “anomaly score” to the respective layer, the graphical representation of which allows the viewer to immediately check all layers built so far at a glance. A new feature is the function of projecting layer data from the workpiece onto the respective camera image. This makes it easier to assess whether a detected defect actually has an impact on the component or is limited to non-critical areas. With this combination of stability, productivity and digitization, the LASERTEC 30 SLM 3. Generation marks a major step towards industrially scalable powder bed production. Using the example of a robot head from the MATRIS light, DMG MORI will be demonstrating such a manufacturing process at Formnext.

The latest development examples show that DMG MORI implements innovative processes related to additive manufacturing on both a technological and economic level. The consulting unit ADDITIVE INTELLIGENCE makes it easier to get started with this topic with in-house experts. They advise and support customers in exploiting the full potential of AM – from the initial idea to design and series production. In combination with the latest machine developments, hybrid process chains and digital tools, this creates a total package that gives companies a real competitive advantage. The production of customer parts can also be implemented in this unit. Today, more than 3,000 components are already manufactured annually for use in Group machines. DMG MORI is thus underlining its role as a partner on the way to the future of manufacturing – and as a driver of a sustainable Machining Transformation (MX) that takes additive technologies out of the pioneering phase and into industrial reality.