There is growing pressure on original equipment manufacturers (OEMs) to deliver products to market at speed while maintaining high production standards, reliability and quality. These pressures show across multiple sectors including agriculture and landscaping, construction and fire and rescue. To achieve this objective, OEMs need to prioritise dependable suppliers that can implement effective and efficient communication technologies within their machines, that will help to speed up development whilst safeguarding machine quality and output. This has led to the implementation of CANbus (Controller Area Network bus) for many suppliers, which is now recognised as a key part of modern machinery when integrating technology between engines and machines.

CANbus and J1939

CANbus allows different components of a machine to communicate with each other via a Controller Area Network (CAN) in real time. Using CANbus makes it easier to connect new components and also makes the implementation easily scalable for each machine.

In addition to CANbus being more convenient, J1939 can be implemented alongside CANbus systems. J1939 is a communication protocol built for CANbus that helps to standardise data exchange between two different components, and is widely used in automotive and industrial applications.

There are numerous elements that make combining CANbus and J1939 beneficial, including easy integration and monitoring, cross-industry application and they also comply with international standards, ideal for globally oriented OEMs.

Andrew Charuta, Regional Technical Service Leader for Electrification at Briggs & Stratton EMEA said: “CANbus is a game-changer because it streamlines how components interact. Simply put, CANbus is a kind of ‘network’ that allows all devices connected to the bus to ‘talk’’ to each other. It is a robust vehicle bus standard designed to allow microcontrollers and devices to communicate with each other without a host computer.“

The advantages of CANbus for OEMs

For OEMs, a CANbus-based system makes life simpler. It reduces the complexity of wiring, which not only makes machines quicker to assemble but also lowers the chances of wiring-related faults. Plus, as CANbus uses a single communication network, integrating new parts can be achieved much faster.

Diagnosing and resolving issues is much easier when working with CANbus. When issues occur in machines, CANbus helps to hone the search for problems in the right direction, which also allows operators to access information from one place, without dismantling the equipment. Compatibility between each component is therefore improved, allowing OEMs to choose the most suitable components for the right machinery. This permits the machine to be built modularly, making it easily adaptable for scaling or transitioning to different international markets without the need for redesigning and resulting in a future-proof communication system and lower total cost of ownership.

The advantages of CANbus for component suppliers

For component suppliers, CANbus offers a clear route to becoming a trusted partner for OEMs. By designing products that are CANbus-compatible, suppliers can ensure their components are integrated seamlessly into complex machines. This increases the likelihood of them being selected by OEMs, but also opens opportunities across multiple industries where CANbus is already established.

CANbus compatibility for suppliers helps future-proof their offering as industries move towards smarter and more connected machinery, components that can communicate effectively are in a better position to meet current and future demand. Compliance with J1939 further enhances their global application by ensuring components meet international standards widely used in a large number of applications.

Integration challenges

OEMs using CANbus and J1939 can still face challenges. Development cycles are shortened due to the new efficiencies, which puts pressure on engineering resources to integrate new systems. A lack of supplier-side documentation and support can also sometimes mean OEMs are left to figure out integration on their own, which may cause operating delays.

How these challenges are addressed

For OEMs sourcing components that are already CANbus-enabled simplifies the integration process. Instead of investing additional engineering time to adapt parts, these components can be connected directly, accelerating development cycles and reducing time to market.

CANbus-enabled components also give OEMs greater flexibility when designing machines, as they are easier to combine with other compatible systems. This not only supports modular machine design but also reduces the likelihood of compatibility later in production.

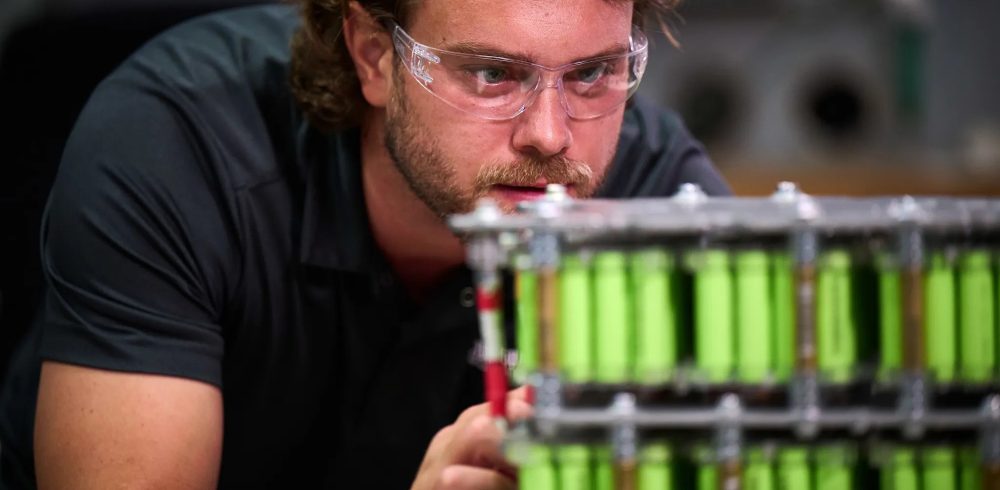

Suppliers across the industry are responding to these demands. Vanguard, the commercial power brand of Briggs & Stratton, for example, offers CANbus-ready petrol engines and battery systems, providing OEMs with power solutions that fit seamlessly into existing communication networks.

Steffen Hoffmann, Engineer at Briggs & Stratton’s Power Application Centre Europe (PACE) said: “As machinery becomes more complex, the ability for components to communicate with each other is essential. CANbus as a common language creates not only additional integration options, it enables suppliers to deliver future-ready solutions. For engineers, that means less time spent on individual solutions and more focus on developing innovative applications.“

Industry applications

CANbus has become a cornerstone of modern machine design across industries worldwide. First proven in the automotive sector, the technology is now applied to a wide range of smaller machines in agriculture, construction, landscaping and emergency services. Its ability to standardise communication, simplify integration and modular design makes it a valuable tool for any market where reliability and efficiency are key.

Vanguard’s CANbus-compatible technology is already in use across a range of industries. In agriculture and landscaping, the Ferris® FRC7 hybrid slope mower uses a 23-horsepower CANbus-capable Vanguard® EFI engine and offers reliable performance for turf and landscaping equipment. While the ELIET® Prof 6 On Wheels shredder runs on either VanguardTM fixed or swappable commercial batteries or combustion engines, and is a good example of how the same machine can use different power sources that can be integrated by CANbus and J1939.

Whilst in fire and rescue, the Rosenbauer Power Aggregate uses the Vanguard® 37-horsepower EFI engine to provide dependability, and rapid start in high pressure situations.

In construction, Kovo Vuijtek’s Scorpick ENTER pick & carry crane powered by two Vanguard fixed batteries is an innovation that scores especially well for indoor applications.

CANbus-enabled batteries

Scorpick ENTER is a good example for how multiple batteries that can communicate via CANbus make energy management in machines more intelligent. When several batteries are used in parallel, the system allows them to share real-time information with each other, ensuring balanced charging and extended battery life.

This capability applies across a range of applications, where the batteries are fixed or swappable. In swappable systems, CANbus also ensures new batteries can be integrated seamlessly, maintaining performance of the machine.

Conclusion

CANbus and J1939 have transformed how OEMs configure their machines. By allowing different components to communicate together, OEMs can reduce wiring complexities, improve compatibility, and identify issues more easily. It also means machines can be scaled and adapted more efficiently.

For OEMs, understanding how CANbus works, the benefits it brings and how to work around challenges, makes the purchase decision easier. No matter the industry, CANbus is an essential communication tool to ensure reliability, efficiency and futureproofing of machines. For component suppliers, ensuring their products are CANbus compatible allows for an increase in applications and markets to deliver to. For example power solutions, which can work in multiple application types, whether it be combustion or electrification. Meaning OEMs can trust in the component suppliers power solutions to fit easily, efficiently and be easily monitored by the operator.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News