Family-owned UK based manufacturer; Yorkshire Precision Engineering have been investing to increase production capacity. The investment has been part of a drive to shorten lead times and provide an unmatched service for their customers. Ensuring they maintain a modern flare with the latest technology, YPEL has invested in the latest GARANT Xtric vices from Hoffmann Group UK, for their CNC machines. This small yet mighty change has seen the company surpass their goal of producing 1000 parts a week and increasing production by almost 100%.

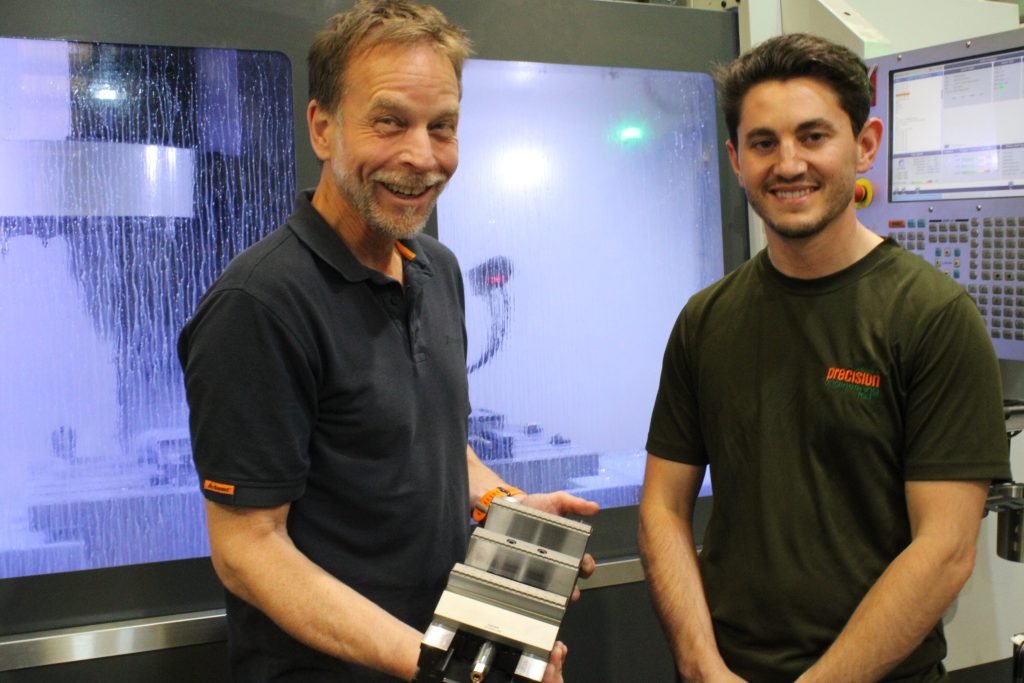

Founded in 2001 by Micheal Laybourne, Yorkshire Precision Engineering produces a range of high quality milled and turned CNC parts. A 2nd generation family-owned business, the company has recently been taken over by brothers Jack Laybourne & Sam Laybourne. Working for the business whilst growing up, the pair have become experts in their field and are eager to invest and improve their services.

With manufacturing accuracy at the heart of what they do, an ambition of theirs has been to increase production capacity without compromising on quality – since taking over the business 4 years ago. Technical Director Jack Laybourne’s aspirations are to streamline the company’s current workflow, make the manufacturing more efficient and diversify into new markets. Successfully working towards that goal, the company opened another site in Keighley and continue to invest.

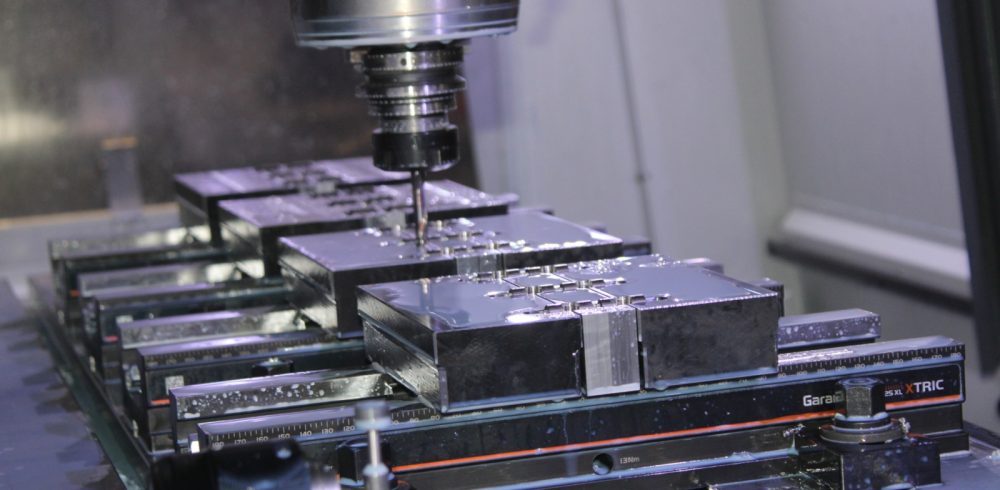

The GARANT XTric vice from Hoffmann Group UK is one of the products that has been making a major difference to YPEL’s production capabilities. Jack Laybourne, Technical Director, said: “previously we were struggling with hitting our target number of parts produced weekly. The new vices from Hoffmann group UK have helped us produce more parts with longer running times on the machines. This allows us to utilise our time better like checking parts whilst the machines run, ultimately producing more parts weekly”.

With their old vices, the company were running two operations at 4-minute cycles – this produced around 4 parts every two minutes. With the new vices from Garant, the company is producing 12 parts every 13 minutes – ultimately making almost double the parts they were previously. What makes the Garant Xtric vice more unique than others on the market is the opportunity to add different jaw types.

This means the company aren’t only saving time for the operators and producing more parts, they can also complete other jobs without taking the vices out of the machine – another invaluable time and cost saver. Jack continued: “Our previous goal was to produce around 1000 parts a week. With the Garant vices, we are producing around 300-400 parts a day.”

Hoffmann Group UK’s support in procuring the new vices has helped solved an ongoing challenge for YPEL, one that could not be solved by previous suppliers. This has given Jack and the team more confidence to try other products from Hoffmann Group UK and trust the advice from their specialists. Jack concluded: “The knowledge that Hoffmann specialists have of their products and of the manufacturing industry is extremely valuable. They have become suppliers we can trust to offer the right solution”.

Hoffmann Group UK is manufacturer and supplier of industrial equipment to more than 135,000 customers across the globe. Headquartered in Germany, the company has 50 subsidiaries including Birmingham, UK. The organisation offers its customers expert advice with specialist consultants in PPE, Cutting Tools, Measuring Equipment and Workstations and Storage. As a manufacturer, Hoffmann prides itself on creating solutions for industry with manufacturers in mind.

Discover the range of products at Hoffmann Group UK products by heading to https://www.hoffmann-group.com/

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News