At the forthcoming EMO exhibition in Hannover, to be held from 22nd to 26th September 2025, DMG Mori under the motto ‘Manufacturing the Future’ will feature in hall 2 more than 40 high-technology production centres, eight of which will be world premieres. In all, 33 automated manufacturing solutions will be on show.

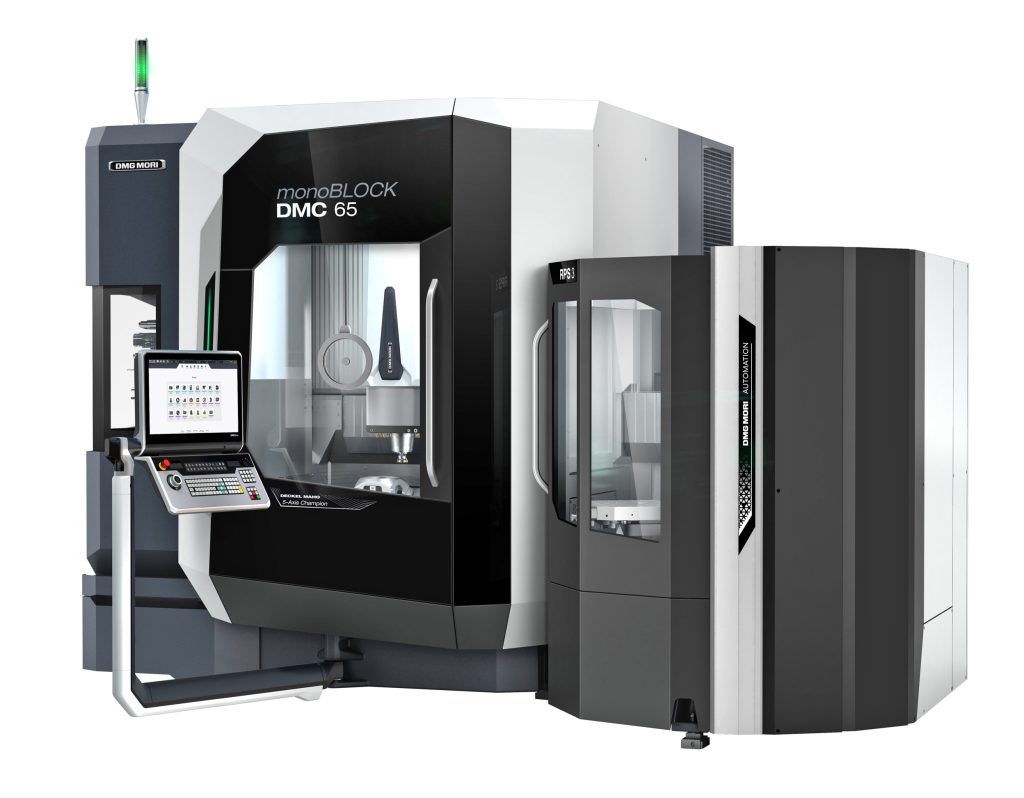

There will be two new 5-axis machining centres, the new DMC 65 monoBLOCK 2 and the DMU 20 linear 3, both vertical-spindle models, as well as a horizontal-spindle DMC 55 H Twin. The ULTRASONIC 60 Precision will go one step further, offering 5-axis milling combined with ultrasonic-assisted machining and a positioning accuracy of 4 μm as standard.

A new, universal turning machine in the portfolio will be the powerful, versatile NLX 2500|1250 2nd Generation. Additionally, with its twin spindles and two B-axis tool carriers, the NZ DUE TC will combine the characteristics of a highly productive production lathe with turn-mill complete machining capability. The DMV 200 and SPRINT 420 lathes will also be new at the show. All of the world premieres may be automated to utilise their production capacity optimally.

A new, driverless transport system for automatically handling tools, material pallets or chip trolleys will be the AMR 1000, further supporting DMG Mori’s provision of autonomous manufacturing solutions. Included in the 33 automated cells on show will be machine pallet storage and handling magazines, AGVs and robotic load / unload systems for components.

To demonstrate process integration, the DMC 125 FDS duoBLOCK μPrecision machining centre will be seen milling, turning and grinding a component in a single clamping. Such a solution frees up capacity on other machines and significantly reduces the need for operator attendance during production. Such a production centre may be utilised for up to 7,000 hours per year. Other technologies such as ultrasonic machining and different types of additive manufacturing processes will be in evidence.

In the context of digitalisation, DMG Mori’s CELOS X app-based control interface supports users from order planning and programming to process optimisation, as visitors that are unfamiliar with the system will learn. All machines fitted with CELOS X benefit from GreenMode, which reduces the energy consumption of the machines by up to 30 percent.

Presenting their products also on the stand will be numerous third-party suppliers of machine peripherals that partner with the machine tool manufacturer under the DMQP (DMG Mori Qualified Products) programme.

Irene Bader, a Board member of DMG Mori explained, “What we are presenting at EMO is more than just technology – it is a glimpse into the future of manufacturing.

“The idea of creating a DMG Mori world in hall 2 is to connect people, industries and innovative technologies to create a shared vision: sustainable, integrated, automated production solutions that meet tomorrow’s challenges today.

“It is a global meeting place for ideas, partnerships and perspectives. Especially for small and medium-sized businesses, we create practical and future-proof concepts that promote competitiveness and innovation.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News