The Push for Electrification in Heavy-Duty Machinery

The shift toward electrified powertrains in off-road, construction, and mining equipment is accelerating, driven by increasing regulatory demands to reduce emissions while enhancing efficiency, safety, and performance. Transitioning from diesel-driven systems to hybrid and fully electric alternatives presents significant engineering challenges, with thermal management being one of the most critical.

Maintaining optimal operating temperatures in high-power battery systems, electric drivetrains, and work functions is essential to ensure performance, reliability, and safety in harsh environments. Without effective cooling, batteries risk overheating, efficiency drops, and thermal runaway—potentially catastrophic failures. To address these challenges, advanced thermal management strategies must be integrated into mobile electrification systems, ensuring cooling solutions are not only effective but also lightweight, compact, and rugged enough for demanding applications.

Parker Hannifin, a global leader in motion and control technologies, including fluid, motion, and thermal management solutions, is at the forefront of engineering comprehensive systems that enhance safety, efficiency, and durability in electrified mobile equipment.

Challenges in Electrifying Heavy-Duty Equipment

Electrification of off-highway vehicles is far from a simple swap of powertrains. Unlike stationary applications with controlled environments, mobile machinery faces unpredictable and extreme conditions, with dynamic heat fluctuations caused by terrain, load, and duty cycles. Key challenges include limited space for cooling components, power density demands, system efficiency, durability under harsh conditions, noise reduction, and ease of integration.

Space constraints are particularly challenging in construction and mining machinery, which were originally designed around diesel engines without considering the additional thermal complexity of battery packs, inverters, and electric motors. Effective cooling requires heat exchangers, hoses, pumps, and reservoirs, yet fitting these into existing platforms without compromising performance or operator safety is difficult.

Power density is another critical factor. Electric motors, inverters, and batteries must deliver high power in compact forms. Battery packs, unlike diesel engines, must operate within narrow thermal windows to maintain efficiency, performance, and longevity. Insufficient cooling causes overheating, power loss, and permanent battery degradation.

Thermal management extends beyond cooling. A growing trend in industrial electrification is the reuse of waste heat to improve overall system performance – preheating fluids, maintaining battery temperature in cold conditions, or enhancing hydraulic efficiency. This reduces energy waste and improves system efficiency, vital for industries prioritizing uptime and energy savings.

Durability is paramount, as off-highway vehicles operate in dusty, freezing, or humid environments. Thermal management components must withstand vibrations, mechanical shocks, and chemical exposure while maintaining performance over long service intervals.

Noise reduction is also increasingly important. As electric drivetrains replace loud diesel engines, auxiliary components like fans and pumps become more noticeable. Minimizing operational noise is critical, especially in urban construction and underground mining where restrictions are stringent.

Finally, simplicity and integration ease are key. The industry is moving toward plug-and-play cooling solutions that reduce installation complexity, minimize failure points, and integrate seamlessly with battery management and power electronics. Simplified architectures reduce manufacturing costs and improve serviceability.

Battery Cooling in Electrified Work Functions

Battery-powered construction and mining machines rely on high-energy-density lithium-ion batteries to power electric drivetrains and hydraulic functions. Battery temperature control limits performance and lifespan; overheating degrades cells, reduces charge retention, and risks thermal runaway.

Hydraulic lifting, drilling, and material handling impose heavy energy demands, causing rapid heat buildup. Unlike diesel engines that dissipate heat via engine cooling, electric systems require specialized thermal management to regulate temperature effectively.

Advanced liquid cooling systems circulate coolant through carefully designed thermal pathways, preventing heat-related degradation. By extracting heat from batteries, inverters, and motors, these systems maintain optimal performance even under high stress. Efficient battery cooling directly affects duty cycle, power output, and long-term reliability, making it a cornerstone of electric powertrain design.

Parker’s Thermal Management Solutions

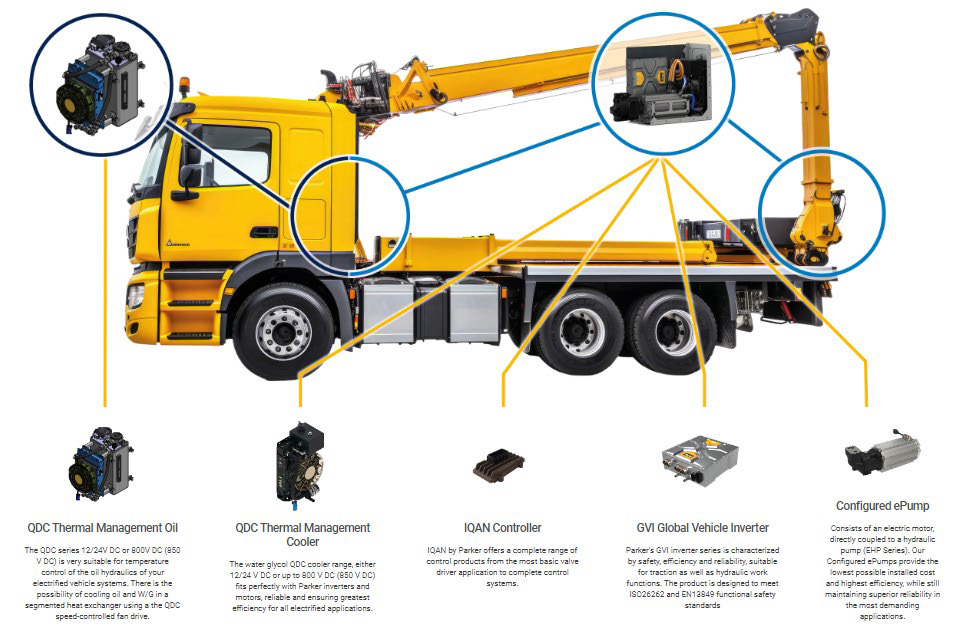

Parker Hannifin offers a comprehensive range of thermal management components tailored to the challenges of off-road electrification. These solutions integrate smoothly into diesel, hybrid, and fully electric mobile systems, ensuring optimal performance and safety in harsh industrial environments.

Key products include:

- Electronic Cooling Hoses and Liquid-Cooled Heat Exchangers: Providing precise temperature control for batteries, inverters, and motors, these flexible components enable efficient, space-saving cooling loops.

- Quick-Disconnect Couplings: Ensuring fast, leak-free fluid connections to reduce downtime and contamination risk – critical for high-voltage battery cooling.

- Integrated Thermal Management Systems for ePTO and Electrified Work Functions: Modular, scalable architectures that maintain efficient power transmission and hydraulic actuation under extreme loads.

- Battery Safety Components: Vent valves and high-performance seals regulate battery pressure, prevent thermal runaway, and protect against contaminants, enhancing enclosure reliability.

- Energy-Efficient Cooling on Demand: Systems that dynamically adjust airflow and coolant flow based on real-time thermal loads, reducing power consumption while maintaining consistent performance and extending battery range.

The Future of Electrification and Thermal Management

As off-road equipment increasingly embraces electrification and autonomy, advanced thermal management will be crucial for maintaining efficiency and reliability. Smart cooling algorithms, predictive maintenance, and energy reuse strategies will further optimize hybrid and electric machines.

Parker Hannifin continues to innovate, delivering fully integrated thermal management systems that help manufacturers overcome space constraints, improve cooling efficiency, and enhance safety. In a rapidly evolving landscape, precise thermal control combined with energy optimization will be key to successful electrification.

With a broad portfolio of advanced cooling solutions, Parker is powering the future of mobile electrification, delivering safety, efficiency, and durability at its core.

By: Andreas Lengnowski, Market Development Manager, Cylinder & Accumulator Division Europe (CADE), and Fabian Brücker, Market Development Manager, High Pressure Connectors Europe (HPCE), Parker Hannifin.

About Parker HannifinParker Hannifin is a Fortune 250 global leader in motion and control technologies. For more than a century, the company has been enabling engineering breakthroughs that lead to a better tomorrow. Learn more at www.parker.com or @parkerhannifin.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News