They not only meet the highest demands in terms of quality and function, but their design has also won numerous awards: the hydraulic chucks for the UNIQ series from MAPAL. Following the IF Design Award 2020 and the Good Design Award 2021, the Aalen-based tool manufacturer finally received the sustainability-oriented Green Design Award in 2024.

When the precision tool manufacturer and technology partner MAPAL completely revised its hydraulic chucks in 2020, the focus was on making the entire product range even more efficient and durable in daily use. The new hydraulic chucks were to be given a uniform appearance – the requirement that the design should guarantee the greatest possible stability with optimum use of resources.

In collaboration with the design agency Ottenwaelder and Ottenwaelder from Schwaebisch Gmuend, the product managers at MAPAL developed a new design concept for the product family. In order to emphasise the uniqueness of the revised chucks, it was named based on the English word “unique”.

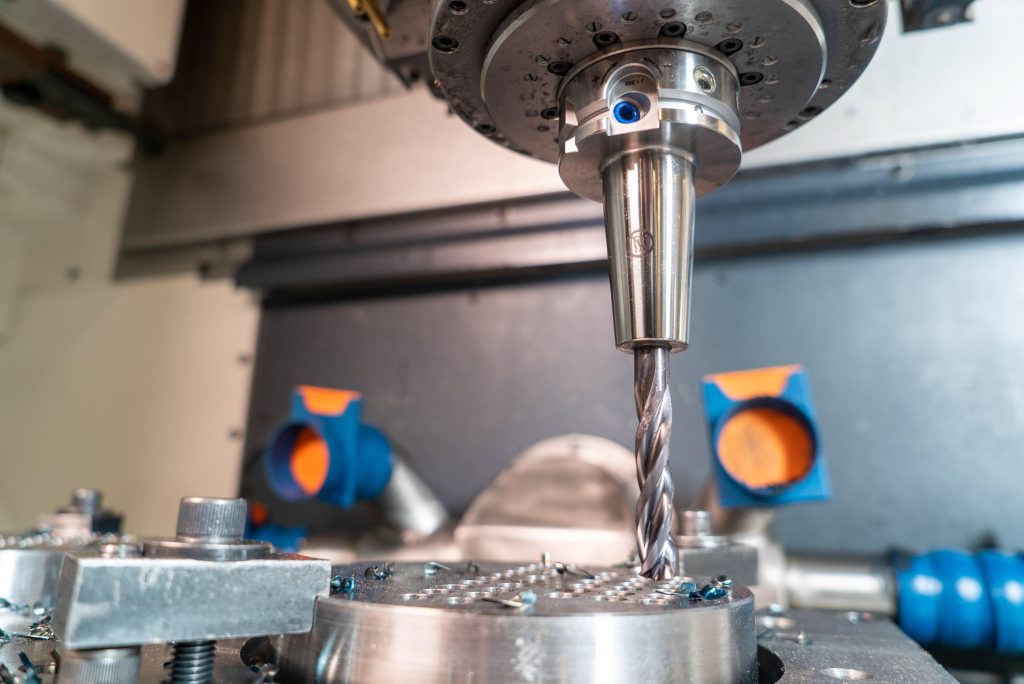

The two hydraulic chuck series – UNIQ Mill Chuck and UNIQ DReaM Chuck – combine MAPAL’s performance promise of quality and function, in particular through an optimum interplay of geometric and functional properties.

Thanks to a polishing process newly developed for the UNIQ series the high-gloss surface of the chuck is more resistant to dirt and corrosion. MAPAL also attached great importance to making the use of the hydraulic chucks process reliability. The blue colouring of the of the actuating screw contributes to this. Specially created signatures also contain handling instructions. “The MAPAL chucks have a significantly unique design language,” says Petra Kurz-Ottenwaelder, Managing Director of the design agency Ottenwaelder and Ottenwaelder.

When the first chucks were available after the development, the agency submitted the UNIQ hydraulic chucks, which were honoured at the iF Award in 2020. This was followed by the Good Design Award in 2021 and most recently, at the end of 2024, the sustainability-oriented Green Design Award, which focuses on sustainability.

“We are proud that we have won several internationally recognized awards with UNIQ,” says Tobias Bayerle. The development of the UNIQ series proves that you can not only win through practicality, but also that product design can offer customers added value. customers through product design. “If you can impress with performance and design, then you’ve done a lot of things right.”

However, it is even more important for Bayerle to emphasise that the UNIQ chucks have been very well received by existing and new customers from day one. “Since the introduction of the UNIQ series, we have always seen exponential growth in this continuous growth in this area,” he says.

Green Good Design Award honors sustainable design ideas

The latest award for MAPAL and the Gmuend-based agency Ottenwälder and Ottenwälder is the Green Good Design Award, which the Chicago Athenaeum Museum of Architecture and Design presents annually to companies and individuals who pay particular attention to sustainable design. The two companies were honored for the new design of the UNIQ hydraulic chuck.

What makes the UNIQ series particularly sustainable

A hydraulic chuck is suitable for reconditioning. If the hydraulic oil is refilled during servicing, the chuck is as good as new and ready for a second service life. A UNIQ hydraulic chuck can handle up to 15,000 clamping cycles, which is well above the average value of a shrink fit chuck.

Shrink fit chucks are energy guzzlers, consuming up to 12,000 kilowatt hours and 3.6 tons of CO2 per year. This is saved by using a UNIQ hydraulic chuck.

In addition, a hydraulic chuck can be changed much more quickly. Shrink fit chucks take between four and six minutes longer, which adds up over time.

Hydraulic chucks are also much safer to handle. With shrink chucks, almost every operator burns their fingers at least once during the hectic working day. With hydraulic chucks, on the other hand, there is no risk of burns.

UNIQ Mill Chuck: Reliable. Dynamic. Agile

The UNIQ Mill Chuck is specially designed for clamping milling tools with HA shanks. Thanks to its high temperature resistance of 80 °C, even with very long milling cycles, it impresses in highly dynamic milling applications, such as SPM (Structural Part Machining), HSC (High Speed Cutting) or HPC (High Performance Cutting), for high-quality components with excellent process reliability and high metal removal rates. It is universally suitable for roughing, semi-finishing and finishing operations.

UNIQ DReaM Chuck, 4.5°: Visionary. Flexible. Economical.

The UNIQ DReaM Chuck, 4.5° is optimized for reaming and drilling applications as well as for use with finishing cutters. It enables maximum rigidity with minimum interference contour thanks to the clamping introduction in the HSK collar and low material usage. The outer contour of the UNIQ DReaM chuck is based one-to-one on DIN 69882-8 for heat shrink chucks. This makes it very easy to switch from shrink-fit technology to hydraulic chucks.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News