APF Services, a small but progressive two-man business specialising in hydraulic repair work, has invested in its first CNC machine, a Proturn RLX 425 CNC lathe with ProtoTRAK® control from XYZ Machine Tools. Despite concerns about the cost and learning curve involved in transitioning to CNC, the portfolio of cost-effective, easy-to-use machines available from XYZ completely allays such apprehensions for small manufacturing businesses. APF Services is a case in point, where the arrival of the new XYZ CNC lathe is driving cycle time reductions of up to 90% on certain jobs.

Located near Peterhead, Aberdeenshire, APF Services was founded in 2012 by Chris Dawson to provide hydraulic repairs for a host of local industries, including agriculture, forestry, fishing, oil & gas, and waste/landfill.

“We have a good regional niche in these sectors,” he says. “However, we were managing our workload using two manual lathes and a manual mill, which started to prompt concerns about getting left behind. Turnaround time is paramount for our customers, with requests for next-day delivery commonplace. However, I’d never dreamed of going into CNC as I didn’t know the first thing about it.”

By chance, Chris noticed that a nearby customer in the forestry industry was benefiting from a range of CNC machines with ProtoTRAK® controls from XYZ.

“I subsequently went to see a demonstration of a Proturn RLX 425 CNC lathe at XYZ’s Scotland facility in Livingston,” he says. “As my first-ever experience of a CNC machine, I wanted to be 100% sure I could get to grips with the programming, but I needn’t have worried. For first-time CNC machinists like me, the ProtoTRAK® control is absolutely excellent. The 15.6-inch touchscreen makes the control simple and intuitive, while the TRAKing® feature allows us to wind the handwheel through the program with complete control, providing peace of mind as we cut our first chips on a new part.”

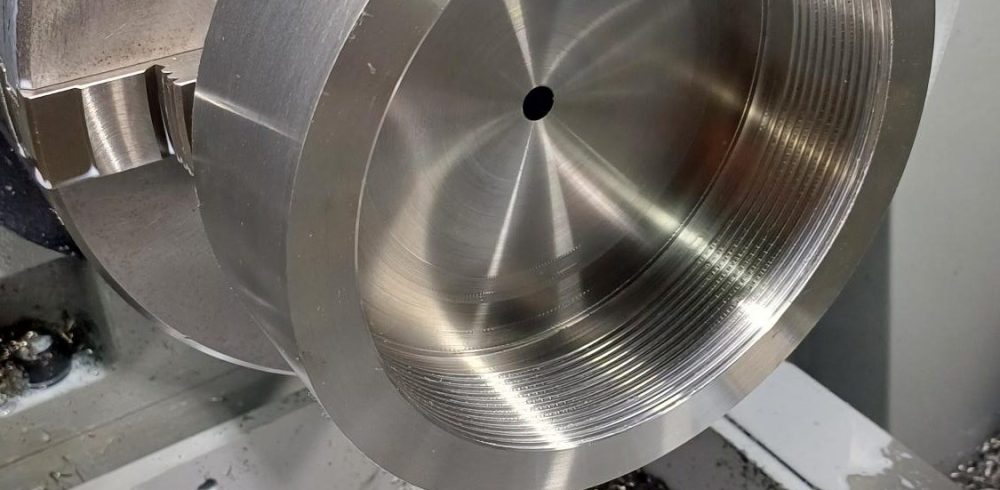

XYZ’s Proturn RLX 425 CNC lathe with ProtoTRAK® control, which is now fully operational at APF Services, offers a 7.5 kW spindle and delivers power through a three-speed headstock running up to 2500 rpm. The machine features an 80 mm spindle bore, provides 700 mm swing in the gap and 480 mm swing-over-bed, and is available with a distance between centres of either 1.25 or 2 m.

“We had our training at XYZ’s Livingston facility and could ask as many questions as we wanted. Nothing was too much trouble.”

APF Services uses its RLX 425 to produce a host of hydraulic cylinder rods, pins and bushes, typically as one-off jobs but occasionally in small batches. Features include threads, shoulders, chamfers, O-ring grooves and circlip grooves.

“With so many different hydraulic cylinder designs, we can find ourselves machining almost anything,” says Chris. “Materials extend from EN8 and EN24T steels, through to chrome-plated steel, stainless steel, and cast steel. Having a machine that’s versatile and quick to program is a real blessing.”

Cycle times are dramatically shorter, as revealed by a recent in-house time study involving a machining operation on a batch of hydraulic cylinder components.

“It took just 4 minutes 30 seconds on our new RLX 425 and we weren’t even pushing it hard,” says Chris. “The same job took 45 minutes on one of our manual lathes. That’s a 90% reduction in machining time.”

The company also reduced the cycle time for hexagon end caps – machined from 9-inch diameter stainless steel bar – from 12 hours to just 2 hours. He also recalls saving a staggering five days of machining time on a batch of cylinder parts.

“We completed them in five days, instead of the 10 days it would have taken us to do them manually. And that’s when we were still learning about the RLX 425.”

According to Chris, customers return because he understands the demands of their industry, particularly the agriculture and oil & gas sectors, as he comes from a farming background. Furthermore, there is little anyone can teach Chris about customer support, having worked in the North Sea drilling and subsea construction industry for many years – and subsequently as a hydraulic mechanic for a major subsea engineering company. With this experience, he knows what is expected of third-party companies and the demands put upon them.

“If one of my agriculture customers damages or even destroys a hydraulic cylinder in the middle of harvest, for example, time is literally money,” he explains. “We can be looking at several days for the delivery of a replacement component in our part of the world, which is disastrous for harvesting. We can measure the broken part (or make it from the carboard cut out that is sometimes supplied), repair it or reverse engineer a replacement in ultra-quick time. Sometimes there are no drawings or CAD models, so it relies on our engineering background/expertise to get these customers going again.”

Fortunately, the arrival of the Proturn RLX 4525 is making the process easier than ever before.

“The speed of the machine and quality of finished parts is top notch. The business was already growing, but the RLX 425 has taken us to a whole new level.”

Such has been the positive experience that APF Services has just ordered another XYZ machine, an RMX 3500 CNC bed mill, again with ProtoTRAK® control.

“Once I’m happy with a supplier they’ll continue to get my business,” concludes Chris. “I like the way I can pick up the phone and get advice from someone in the UK. It feels like we’ve got proper support with XYZ. This level of customer service is priceless for a small company like ours, which is new to CNC machining and has customer jobs that often cannot wait.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News