Polestar, the cutting-edge electric vehicle manufacturer, and MBA Polymers UK, a global leader in plastics recycling, have signed a collaborative agreement aimed at accelerating the UK towards a circular economy for electric vehicles.

This groundbreaking collaboration will encourage the entire automotive industry to rethink what’s possible when it comes to recycled plastics, by integrating more post-consumer materials into interior parts for luxury vehicles.

The partnership between MBA Polymers UK and Polestar will enable a circular material flow for end-of-life vehicle (ELV) plastics, meaning less materials from ELVs end up in landfill and less carbon is emitted during a vehicle’s manufacture.

Draft amendments to the ELV Directive by the EU Commission will require the automotive industry to ensure that at least 25% of plastic used to build a vehicle comes from recycled sources – of which, 25% is to come from recycled ELVs.

Achieving full climate neutrality is a complex task, one which Polestar recognises and seeks to attain through partnerships with specialist and industry leading businesses, and MBA Polymers UK is well-placed to rise to this challenge.

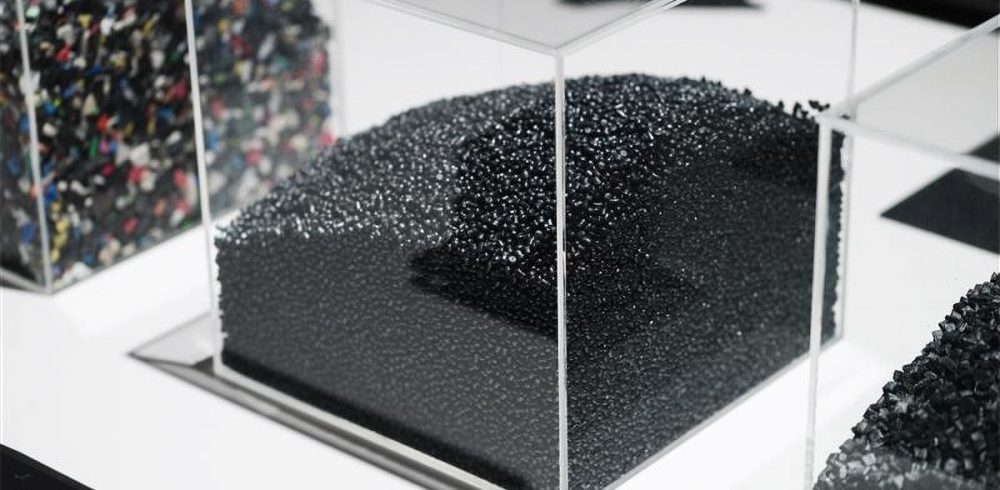

As world experts in recycling automotive plastics, MBA Polymers UK takes valuable plastic bound for landfill, and transforms it into high quality polymers, which have a considerably lower carbon footprint than the virgin equivalent. As part of EMR, the global leaders in sustainable materials, the company has also committed to becoming carbon neutral by 2040 and, through its sustainable manufacturing approach, is devoted to creating a closed loop circular economy.

The partnership follows the launch of MBA Polymers UK’s new ABS (Acrylonitrile Butadiene Styrene) polymer, ABS 4125 UL, which contains 95%+ post-consumer recycled content. The UL certified product provides a revolutionary, high-quality recycled alternative to the plastics used in electronics and automotive manufacturing, reducing the demand on the Earth’s depleting resources.

Transition

Paul Mayhew, Director at MBA Polymers UK, said: “As a leader in plastics recycling, we are dedicated to offering solutions to sustainability challenges and we are proud to partner with such an influential brand as Polestar. MBA Polymers UK’s expertise, combined with our state-of-the art technologies, will support this transition to high quality recycled plastics, enabling Polestar to truly transform the automotive industry and help to safeguard the planet for future generations.”

Ross Kelk, Chief Engineer Interiors from Polestar UK R&D, added: “We are delighted to welcome MBA Polymers UK as a partner. Aligned in our sustainability goals, MBA brings a wealth of expertise and innovation to the project. As an industry leader in vehicle recycling and the sustainable production of high-grade polymers, MBA Polymers UK will play a key role in supporting Polestar’s pursuit for a carbon neutral car in the future.”

For more information on MBA Polymers UK visit our website at mbapolymers.co.uk

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News