ArcFlow is an AI-Enabled Cloud ERP System tailored for SME Manufacturers. Harnessing advanced artificial intelligence, we empower businesses to make informed decisions and boost productivity using their existing resources. ArcFlow is your key to optimised operations and growth.

How does ArcFlow differ from conventional ERP systems?

ArcFlow AI benefits SMEs by automating repetitive tasks and generating precise forecasts, which frees up valuable resources and drives business growth. This advanced automation reduces manual effort, allowing teams to focus on strategic activities while ensuring accurate, data-driven decisions. With enhanced forecasting and operational efficiency, SMEs can scale effectively and make informed choices that support long-term success.

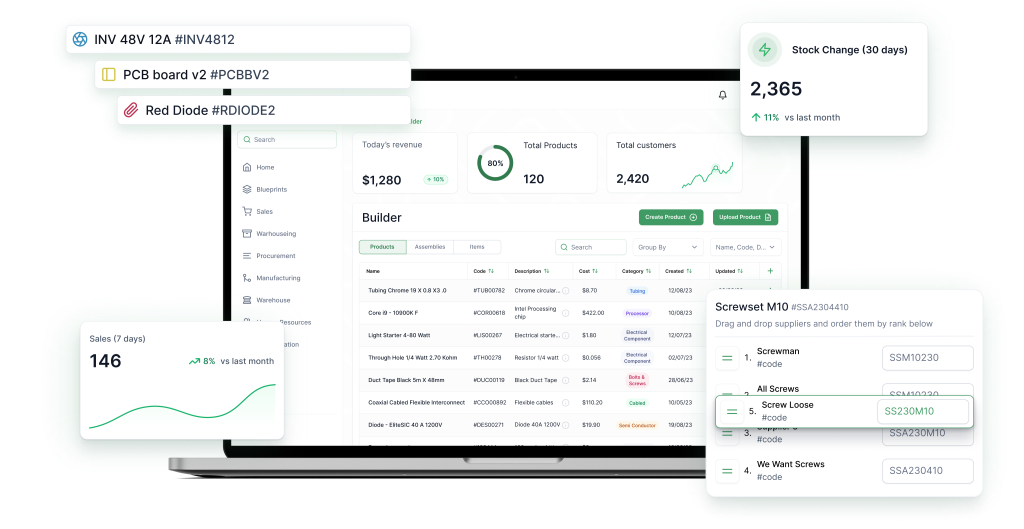

ArcFlow is an end-to-end ERP system providing real-time capabilities and seamless data flow between interconnected modules. Each module handles its own workflows, with outputs automatically feeding into the next, ensuring smooth operations and efficient decision-making. By managing the entire business lifecycle within one system, ArcFlow eliminates data silos, enhances efficiency, and boosts overall performance.

ArcFlow surpasses conventional ERP systems by leveraging advanced AI to adapt to dynamic manufacturing needs. While standard ERPs offer basic MRP functionality, ArcFlow integrates real-time data from inventory, production plans, reserved stock, and incoming orders for precise production requirements. Its AI models, considering 36 and 27 variables respectively, optimize order planning and production suggestions. ArcFlow simulates production scenarios, adjusts forecasted timelines, and automates Purchase Order (PO) creation for Manufacturing Orders (MO), addressing forecasted shortages and maintaining minimum stock levels. This makes ArcFlow a comprehensive and intelligent solution for modern manufacturing.

How does ArcFlow help mitigate risks associated with adopting digital tools for SME manufacturers?

We mitigate the financial risks for SME manufacturers by offering a no-cost implementation process. Our internal data team ensures a smooth transition by cleaning and migrating your data onto our system, providing a successful implementation. Additionally, we operate on a straightforward monthly license fee, with no hidden costs or long-term contract commitments.

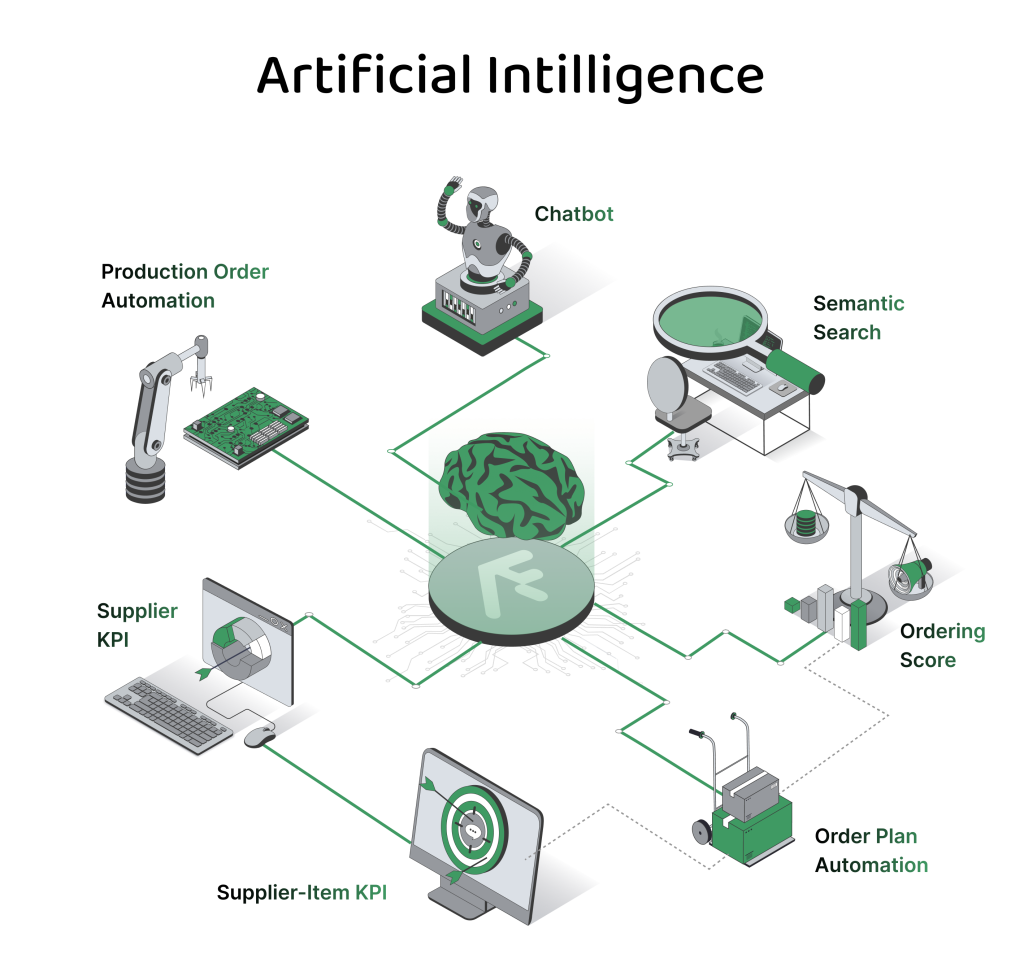

What AI features do you offer, and how do they benefit SME manufacturers?

ArcFlow’s key AI features include Supplier KPI and Selection, Order Plan Automation, and Production Order Automation, collectively utilizing over 110 input metrics to deliver precise output suggestions.

As SMEs scale, ensuring supplier quality across expanded regions becomes crucial. Our Supplier KPI system ranks suppliers based on cost, delivery, quality, and more, providing procurement suggestions that ensure SMEs select the most suitable suppliers for each production order.

Order Plan Automation recommends items and quantities based on various metrics such as sales demand, inventory levels, production plans, and lead times. This automation replaces the time-consuming manual task of creating order plans, allowing SMEs to reallocate human resources to critical business areas, ensuring they have what they need without overstocking or shortages.

Production Order Automation suggests which products and assemblies should be manufactured, considering multiple metrics. This automation frees production managers from planning tasks, enabling them to focus on other essential business areas.

“We have completely transformed an SME’s order planning process, reducing their order plan creation time from four weeks to just five minutes. Our AI provides suggestive outputs that managers can review and adjust, ensuring optimal and informed decision-making,” said James Westraadt, Machine Learning & AI Engineer at ArcFlow.

Which modules does the system cover and what makes them unique?

Blueprints

The Blueprints module revolutionizes digital creation and management for your manufacturing items, assemblies, and products. Key attributes assigned feed into ordering, sales, and storage processes for intelligent management and forecasting. It features a visual routing builder for planning and sequencing operations, seamlessly integrating with production processes to generate and schedule job cards. This module underpins production scheduling, planning, and capacity management, enabling intelligent forecasting and streamlined maintenance.

Warehousing

The Warehousing module offers a multi-warehouse structure for efficient inventory management. It tracks and records all transfers, enhances stock control with automated minimum and maximum holding levels, and integrates with sales, procurement, and manufacturing for precise forecasting. This module supports inventory forecasts and optimal stock levels, preventing overstocking and shortages. The Inventory Management sub-module enables accurate stock takes by comparing physical counts with virtual quantities, addressing discrepancies to maintain precise stock balances.

Procurement

The Procurement module streamlines the entire procurement and supply chain management process. It creates material orders by analyzing 37 variables, including sales orders, stock levels, supplier KPIs, and production plans, to adapt to operational changes. Beyond supporting RFQs, POs, and invoicing, the module recommends optimal suppliers based on real-time data and parameters, ensuring efficient and effective procurement decisions.

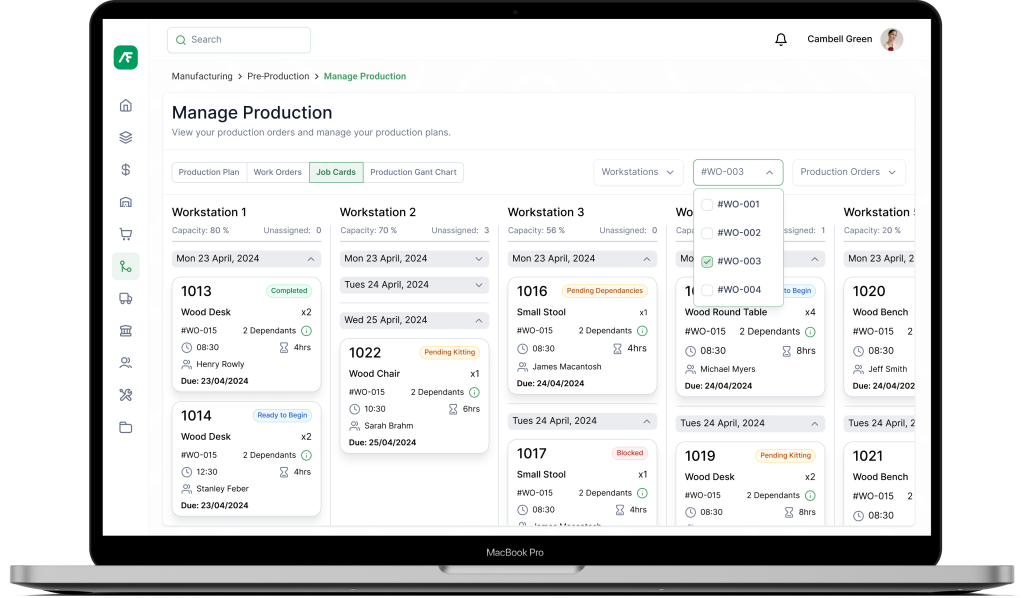

Manufacturing

The Manufacturing module enhances production management by integrating planning, scheduling, capacity, and execution into a cohesive system. It efficiently manages all preparatory tasks, including generating detailed production plans and schedules through work orders and job cards, ensuring a structured start to production. Real-time analysis provides comprehensive oversight of work-in-progress, monitoring employee activities, workstation performance, and the status of assemblies and products, thereby maximising production efficiency and visibility.

Sales

The Sales module optimises sales management by empowering employees to efficiently handle customer relationships, generate quotes, sales orders, and invoices, and track order fulfilment. Personalised dashboards offer sales personnel real-time performance metrics and insights into sales trends. The Customer Management sub-module provides a comprehensive view of customer profiles—active, inactive, and prospective—with detailed analytics and metrics. Seamlessly integrated throughout the system, the Sales module ensures informed decision-making and streamlined operations.

Fulfilment

The Fulfilment module oversees the processing of customers’ pending and completed sales orders, encompassing picking, packing, and customer delivery.

Document Hub

The ArcFlow “Document Hub” serves as a centralized document repository for viewing and managing all documents uploaded onto the system.

What customer support is available after system implementation?

ArcFlow includes integrated app support functionality, enabling you to receive on-demand assistance during your daily operations and use of the ArcFlow system. ArcFlow engineers will provide real-time support through messaging, screen sharing, and audio features, ensuring your operations continue smoothly without disruptions.

Website: www.getarcflow.com Contact: matt.scott@arcflow.co

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News