Schwäbische Werkzeugmaschinen GmbH (SW) will be presenting two innovations at AMB 2024 in Stuttgart from September 10 to 14. For the first time, SW will provide insights into the efficient production of large parts for the aerospace industry and giga-castings with the BA space3-22 at its 399 square meter booth (10B51) in hall 10. In addition, the world market leader for multi-spindle machining centers will present the world’s first machining center for multi-spindle power skiving, the BA W06-21.

Under the motto “best per part.”, Schwäbische Werkzeugmaschinen GmbH (SW) offers multi-spindle machining centers that derive maximum added value from manufacturing processes. “At this year’s AMB, we will showcase how we use this principle to develop future-oriented production technology for our customers’ individual demands,” explains André Harter, Head of Marketing and Business Development at SW.

Focus on giga-castings und aerospace

At the leading international trade fair for metalworking, Schwäbische Werkzeugmaschinen will be focusing on its Smart Manufacturing Solutions for the production of large components. In the electromobility and aerospace sectors in particular, the trend towards very large components made from a single casting or from the solid material will continue in 2024. This allows components such as underbodies, subframes or complete battery housings for electric vehicles to be produced efficiently. With the introduction of the new, multi-spindle BA space3-22 at the beginning of the year, SW is setting standards in the efficient production of large and complex components. “The BA space3-22 combines maximum precision with short machining times for demanding components, such as those involved in the giga-casting of large components in the field of e-mobility,” explains Harter. “We have thus further advanced the paradigm shift towards e-mobility and established ourselves as a pioneer in the machining of complex components such as battery housings.”

The BA space3-22 is designed for precise machining of large light metal workpieces and offers maximum flexibility thanks to two independent three-axis units in box-in-box design, optionally with five-axis machining. For large parts, both spindles can work simultaneously on a workpiece and change tools independently. Linear and torque motors in the feed axes ensure maximum dynamics, precision, and fast cycle times. At AMB, SW will demonstrate the versatility of the BA space3-22 with an underbody for an automotive supplier and wing ribs for an aircraft body.

World premiere: Multi-spindle Power Skiving

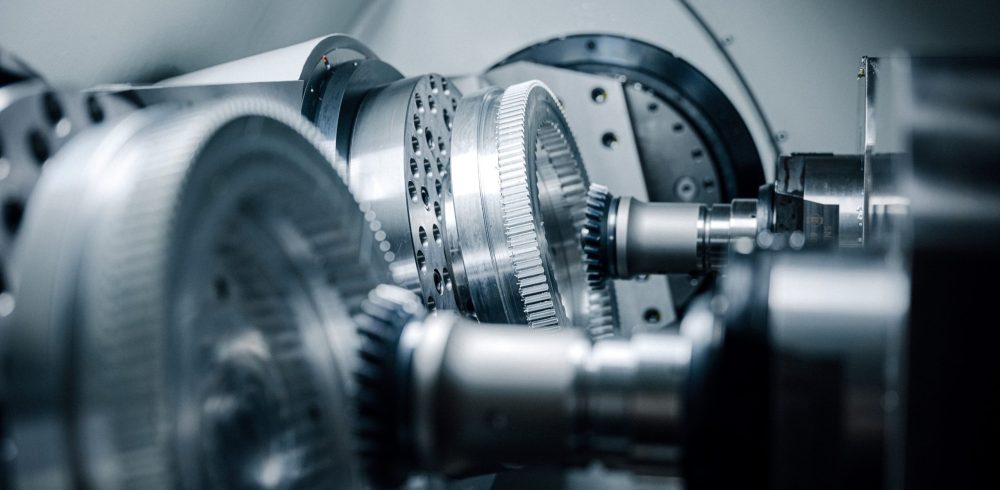

With the BA W06-21, SW will also present a world first at the booth: SW is the only supplier in the world to offer a multi-spindle machining center for power skiving, maximizing productivity in gear cutting. Power skiving, a high-precision cutting process for the efficient production of gears and internal gearing, plays a particularly important role in electromobility to improve the accuracy of transmission components. “The BA W06-21 with power skiving technology reduces production time by up to 50 percent compared to conventional processes,” explains Patrick Schneider, Product Manager at SW. “Thanks to multi-spindle machining in a single set-up, we achieve maximum production output with maximum flexibility – a clear added value for our customers.” The BA W06-21 achieves accuracies up to quality class IT5 and enables roughing and finishing operations as well as additional machining of workpieces in a single clamping. This effectively eliminates tolerance losses due to reclamping. Dynamic travel speeds of up to 120 m/min and a directly driven rotary axis with 1,200 rpm also ensure extremely short main and auxiliary times. The booth will additionally feature a simulation of the TopRob6 robotic solution loading the BA W06-21.

Global presence

Visitors to the booth will be able to see the versatility of SW solutions for themselves: components from various industries will be displayed on a workpiece wall to illustrate the wide range of applications for SW machines, including information on sustainable processing methods. For example, energy-saving friction stir welding, which is used primarily in the aerospace and e-mobility industries, can be used to produce high-strength joints of light metals without melting. In the area of Industry 4.0, the SW team will present its latest developments in the areas of connectivity and digital services – and is looking forward to a lively exchange on the topic of AI in production.

In addition to the two large SW machining centers, SW will also present the ENSHU GE 480H, a single-spindle machining center from its new Japanese cooperation partner ENSHU. This service and sales partnership, which has been in place since autumn 2023, combines the engineering expertise of both companies. “The ability to act globally and at the same time locally and close to the customer is crucial today in order to succeed in the international market,” summarizes André Harter. Accordingly, SW has been expanding its global presence, most recently with new offices in Turkey, South Korea, and Hungary. “We are looking forward to meeting customers, partners, and long-standing contacts from all over the world at the leading international trade fair for metalworking,” says Harter of AMB. “The diversity of visitors at the fair also reflects the range of applications for which we develop customized solutions together with our customers.”

Schwäbische Werkzeugmaschinen GmbH (SW) at AMB Stuttgart, hall 10, booth 10B51, September 10-14, 2024. For more information, visit: http://www.sw-machines.com/en

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News