In 2022, EMR Reusable Steels launched one of the most exciting new construction materials to reach the market for decades. Our high-performance reusable steel sections are sourced from existing end-of-life buildings, before being carefully analysed in our state-of-the-art laboratories and processed for their second life.

They are then delivered to customers to create the next generation of sustainable homes, workplaces, and public buildings.

By removing the need for virgin iron ore to be mined and transported around the world and avoiding the carbon-intensive processes required to produce new steel, EMR Reusable Steels take the World Steel Association’s estimate for the average impact of this material’s production – 1,850kgCO2e per tonne of steel produced – and reduce this down to 47kgCO2e.

This means that construction firms that choose to use EMR Reusable Steels’ sections are opting for a product that has 97.5% less embedded carbon than traditional steel. As the industry looks to adopt the Part Z update to UK building regulations, using reusable steels will, therefore, provide a range of financial and sustainability benefits for their projects.

This is a bold claim – and one that is supported by EMR Reusable Steels achieving the world’s first EPD (Environmental Product Declaration) for a reusable steel product – but it is fair to ask how it came upon the figure of 47kgCO2e.

Third party

I’d like to take this opportunity to share our workings.

Firstly, it’s important to emphasise that we have partnered with a third-party consultancy – Metsims – to create a lifecycle analysis of our reusable steels. This process is verified by academics at the LCA (Life Cycle Assessment) Studio in Prague who are, in turn, monitored by EPD International to ensure that they are rigorous and transparent in their operations.

Calculating the emissions for our products required us to use a mixture of our own data and industry-agreed emissions estimates, where we did not have this information – specific to our business – available.

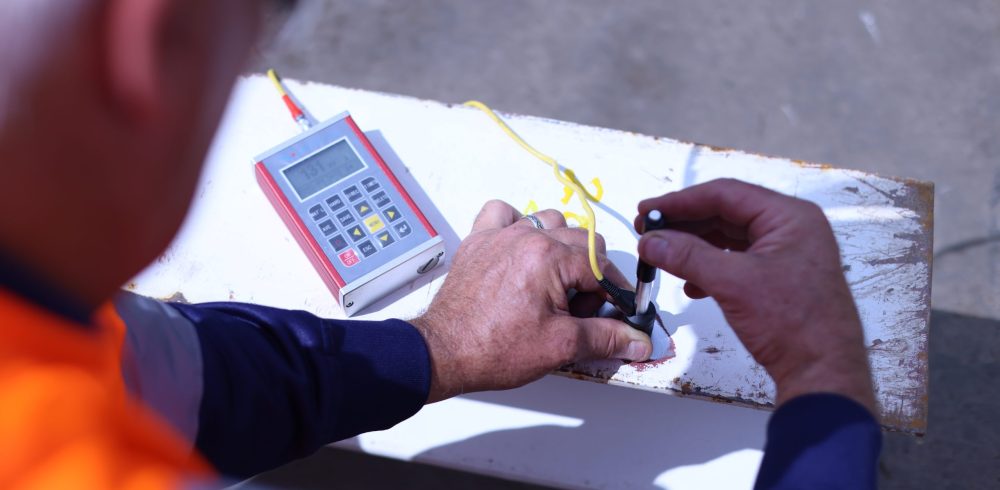

Wherever possible, EMR Reusable Steels used its own – independently verified – data on the emissions we created, as this provided the most accurate picture of the impact our business has on the environment. This included our use of renewable electricity and road transport and had the benefit of reflecting the individual locations, processes, and operations of each of our sites.

If this information wasn’t available, the numbers we used came from third-party emissions data sets – such as SimaPro, ECOINVENT and ICE – all of which have been certified by EPD International.

By bringing our figures together with those provided by these industry-recognised data sets, we have created an accurate assessment of the emissions related to the removal, processing, and delivery of our reusable steels. Best of all, it is verified by an Environmental Product Declaration – a world first for a product like this.

ISO

And that’s not all.

In addition, EMR Reusable Steels meets the standards of ISO14025, ensuring that the reusable steels we produce achieve the quality and sustainability specifications that our customers rightly demand.

As you can hopefully see, EMR Reusable Steels has gone to considerable effort to ensure that the potential benefits of using our products are not only clear and measurable, but also that they have been verified by independent industry experts at every stage.

By doing so, we can confidently state that EMR Reusable Steels’ product has an embedded carbon impact of 47kgCO2e per tonne. Our customers can use this verified data to make an informed decision about their material choices.

Over the coming decades, the journey to net-zero will represent the biggest challenge and opportunity to businesses across the construction industry. EMR Reusable Steels offers construction firms a way to continue using the skills and methods upon which they have relied for generations, but with a far lower carbon impact.

And by doing the hard work of accurately calculating our emissions – and doing so in a transparent and externally-certified way – our customers can continue their work in the knowledge that they are helping to reduce the industry’s carbon impact.

To find your nearest EMR site visit: emrgroup.com

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News