New research from Siemens Financial Services (SFS) estimates the significant energy savings manufacturers could make through a wide scale deployment of energy-as-a-service arrangements.

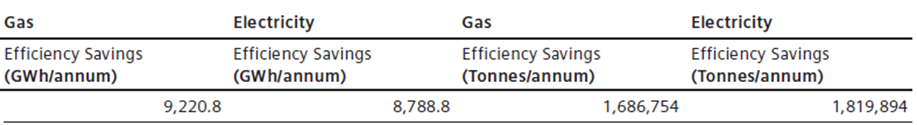

Entitled Accelerating Change, SFS’ report reveals that the manufacturing industry in Great Britain could potentially save over 3 million tonnes (or 18,000 GWh) of gas and electricity per year by adopting energy-as-a-service financing structures. To put this into context, this estimate comes close to meeting around two thirds of official climate targets for this sector. The study also breaks down savings opportunities for British regions.

This is especially important to manufacturers in light of regulatory and financial pressures to minimise carbon emissions by reducing energy use in manufacturing processes. These pressures are all the more urgent as shareholders are increasingly aware of how fuel costs, network costs and poor energy purchasing decisions are harming their investments. However, affording the substantial technology investment to achieve energy savings/decarbonisation targets remains a challenge, especially in a time of rising input costs and volatile industrial demand.

As the report makes clear, new business models, known as Energy-as-a-Service arrangements or energy performance contracting, can secure these operational cost reductions without putting pressure on capital resources and ensure expected savings are realised. Such financing schemes remove the need for a manufacturer to deploy its own (scarce) capital. Instead, the manufacturer is charged a monthly fee against the delivered cost savings, sometimes producing a net operational benefit. Moreover, an Energy-as-a-Service provider covers all aspect of transformation, including installation, operation, performance management and maintenance.

Carolyn Newsham, Digital Industries Financing Partner at SFS, comments, “Net zero is looming and, as one of the largest emitting sectors, manufacturing industry must take serious steps towards decarbonisation. Investing in energy efficiency not only helps manufacturers meet regulatory demands but it is also vital to driving down costs and enhancing competitiveness.”

Download the report here

*Relative sizing of gas and electricity in GWh to CO2e conversions may invert because the conversion factor for electricity is higher than that of natural gas. Conversions performed using Carbon Trust data: carbontrust.com/our-work-and-impact/guides-reports-and-tools/energy-and-carbon-conversion-guide-for-reporting

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News