Industrial Bakery Increases Throughput, Lowers Errors with Zebra Technologies Machine Vision : Powerful machine vision software solves complex packaged food challenges

Zebra Technologies Corporation (NASDAQ: ZBRA), a leading digital solution provider enabling businesses to intelligently connect data, assets, and people, today announced that an industrial bakery has secured lower error rates and higher throughput of goods with a modern machine vision solution using Zebra’s Aurora Design Assistant™ machine vision software.

The bakery can now inspect its full range of breads using a single machine vision solution, and carry out efficient, automated picking with a robotic grip handling between 25 and 30 packages per minute, without damaging bread or packaging. It’s estimated that the new solution has secured a 75% cost saving compared to traditional camera and lighting inspection approaches.

The industrial bakery approached KINE, a Finnish headquartered provider of turnkey robotics solutions for the food and beverage, logistics, semiconductor, and other manufacturing industries. Together with OEM Finland Oy, a Zebra registered industrial automation system integrator and an advanced machine vision specialisation partner, they were tasked with developing a solution that would overcome several challenges.

A manual process was being used to remove and deposit bags of bread loaves and rolls, which was potentially error-prone and less efficient as irregular bread production sizes and shapes made it difficult to determine their location and orientation on the conveyor belt. Transparent plastic packaging also made detection difficult with optical sensors due to low contrast levels and partial reflections.

“We decided to leverage Zebra’s Aurora Design Assistant machine vision software for its versatile, powerful capabilities that provide the robustness and integration needed to visually inspect the variations in packaged bread,” said Kimmo Salonen, Chief Technology Officer, KINE.

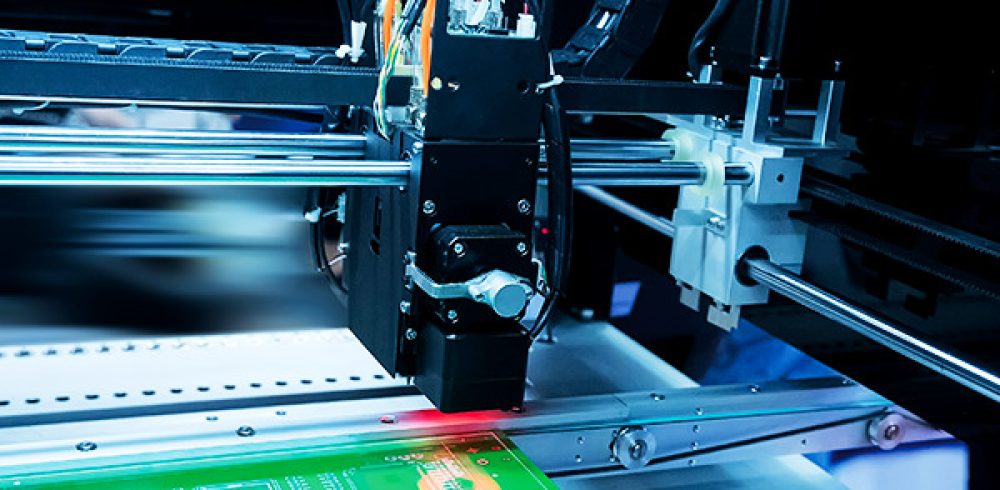

The new system consists of a programmable logic controller (PLC), robotic grip, 3D time-of-flight camera and Aurora Design Assistant software, which has eliminated the need for multiple cameras and lighting and reduced contrast and reflection problems.

“Basic implementation of the vision system took about one day,” said Sami Sinisalo, Robotic Specialist, KINE. “Testing, adjusting, and fixing took about 80 hours, including time calibrating the robot. That’s a great turnaround and drastically less than what we’d typically have to do for a new 3D install without powerful and user-friendly software.”

The camera is placed above the conveyor belt, with inspection flowcharts created in Aurora Design Assistant. The camera takes up to 30 frames per second, recording the bread surfaces as a point cloud with over 300,000 XYZ coordinates. The data is sent to Aurora Design Assistant which converts the data into a depth map for analysis, using 2D vision tools to determine grip points for the robot.

“Challenging manufacturing environments with high levels of compliance and wide variations in components and finished products require powerful machine vision systems to deliver needed outcomes,” said Jason MacDonald, Senior Account Manager, Machine Vision EMEA, Zebra Technologies. “Zebra’s high-performing Aurora machine vision software is moving industries forward and overcoming the problems of legacy systems faced by customers and machine builders.”

KEY TAKEAWAYS

- KINE and OEM Finland Oy were tasked with developing a solution to support an industrial bakery facing several visual inspection and quality control challenges.

- An autonomous machine vision system was created, using Zebra’s Aurora Design Assistant, integrated with a 3D camera and robotic grip.

- The new solution has resulted in lower error rates, higher throughput of goods, and efficient, automated picking. Read the full case here.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News