Rolls-Royce, Landmark and ASCO collaborate on CO2 recovery power generation solutions

- Cooperation plans to develop solutions for clean power generation with carbon capture from gas reciprocating engines

- Captured CO2 will be available for use in industries such as food, Efuels, sustainable aviation fuels (SAF), cement and plastic production

- First of-its-kind flexible power generation and carbon capture plant currently under construction in Nottinghamshire, UK

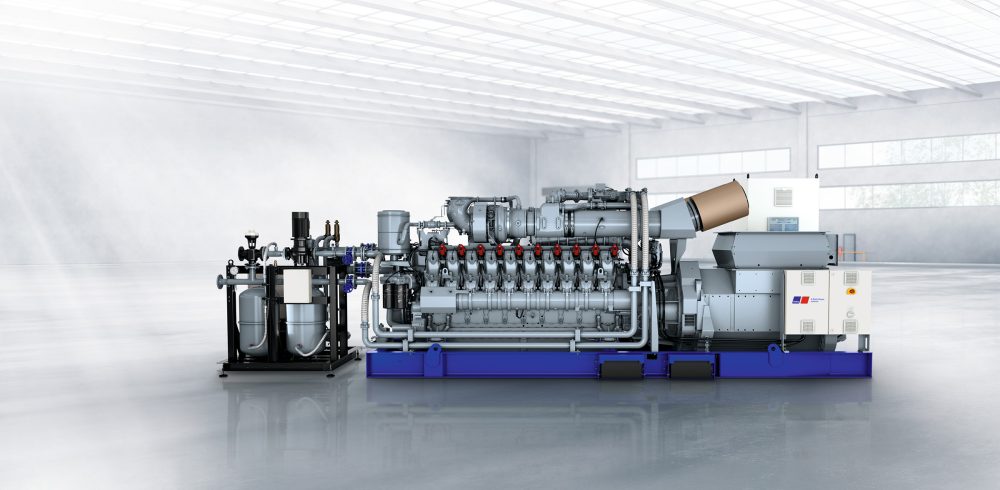

Rolls-Royce, ASCO Carbon Dioxide Ltd (ASCO), and Landmark Power Holdings Limited (LMPH), have signed a Memorandum of Understanding (MoU) aimed at developing scalable solutions for clean power generation with carbon capture from mtu gas reciprocating engines. This strategic partnership will help enable power generation customers to achieve their net zero ambitions and marks a significant step towards addressing climate change.

“Power generation is a highly attractive, growing market segment and an area of strategic focus for Rolls-Royce, where partnerships can help further grow market position and broaden its power generation offering, as set out at last November’s Capital Markets Day”, said Tobias Ostermaier, President Stationary Power Solutions at Rolls-Royce Power Systems. Rolls-Royce is committed to becoming a net zero company by 2050 and supporting customers to do the same.

CO2 capturing for food, Efuel, cement and plastic production

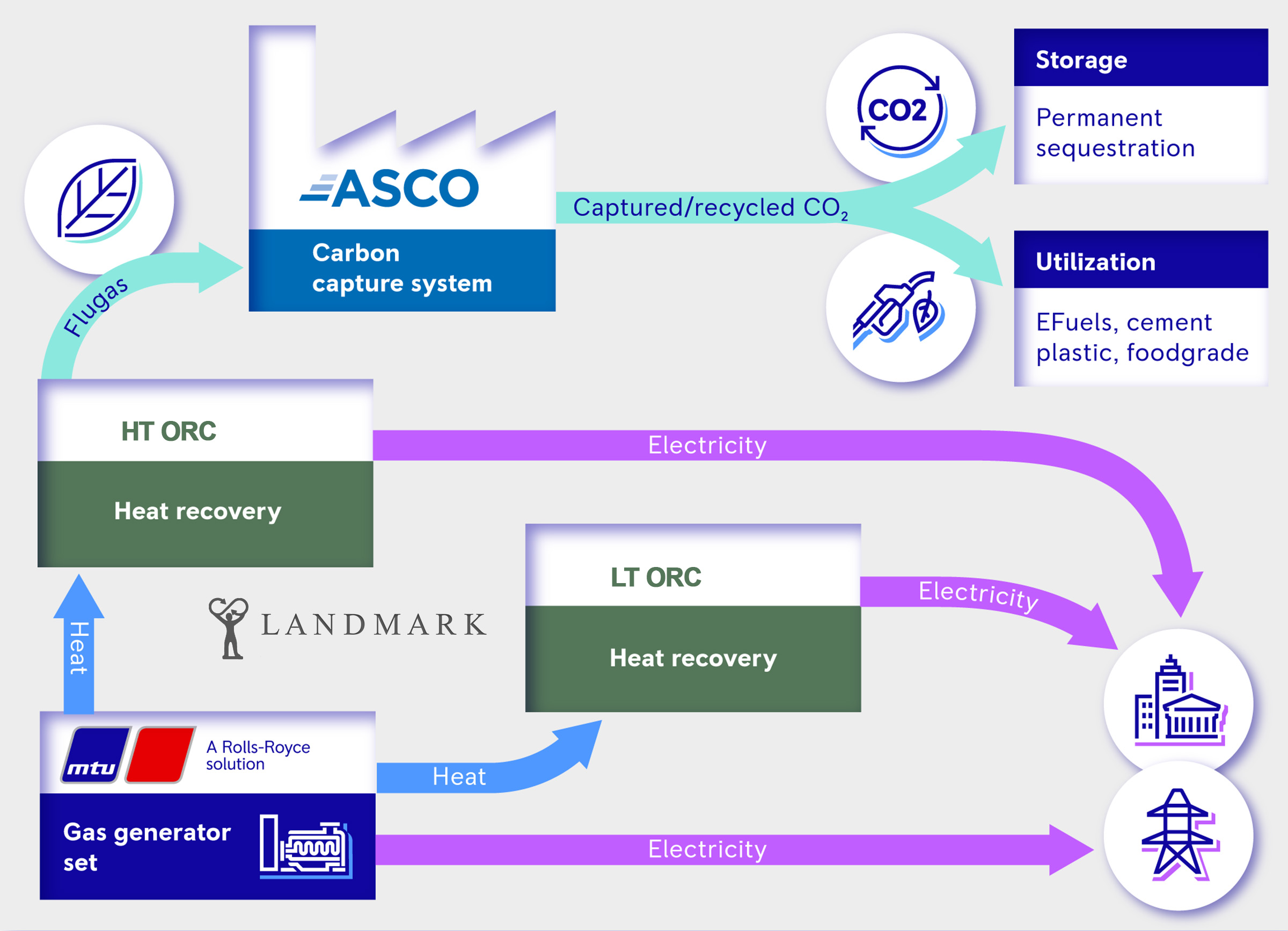

The plan is to make the captured CO2 available (utilisation) for use in various industries such as food production, Efuels, sustainable aviation fuel (SAF), cement and plastic production (utilisation). The captured CO2 will also be ready for transportation should permanent sequestration be preferred (storage).

Rolls-Royce, ASCO and Landmark Power Holdings plan to develop scalable solutions for clean power generation with CO2 recovery from mtu gas combustion engines. The captured CO2 is to be made available for use in various industries such as food production, efuels, sustainable aviation fuel (SAF), cement and plastics production (recycling).

Partnership brings together collective expertise of three leading companies

Rolls-Royce is contributing its extensive experience and global network in the field of decentralized power generation to the cooperation through its Power Systems division with the mtu product portfolio. The contribution of LMPH, a developer of high-efficiency Combined Heat and Power (CHP) projects, is its patented FLEXPOWER PLUS® concept, combined with technical expertise and patented technologies. ASCO has over 50 years of experience in developing and building carbon capture (or CO2-Recovery) plants and will be providing valuable insights and solutions from the carbon capture industry.

Tobias Ostermaier, President Stationary Power Solutions at Rolls-Royce Power Systems, said: “We are convinced that CO2 capture and storage systems in combination with our mtu gas gensets are an important building block on the way to Net Zero. As a complement to renewable energy sources, internal combustion engines can already provide clean, cost-effective and extremely reliable power generation.”

Mick Avison, founder and managing director of Landmark Power Holdings, said: “This partnership is an important milestone in our collective mission to combat climate change and promote clean energy practices.”

Ralph Spring, CEO of ASCO Carbon Dioxide, explained: “We want to serve hard-to-abate industries with a cost-effective solution and this cooperation is a huge step into the right direction.”

First plant under construction in UK

The technology that will be used in the scalable solution is already showcased in a first- of-its-kind decarbonised flexible power generation and carbon capture plant that is currently under construction in Rhodesia, Nottinghamshire in the UK. The Rhodesia plant is the first developed under the Landmark Power Holdings, FLEXPOWER PLUS® concept for flexible power generation with natural gas-powered mtu engines and ASCO carbon capture technology. The plant will support the UK electricity grid, providing power for those living in the area, while turning the resulting CO2 emissions into food-grade carbon dioxide.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News