With the space station, she found 3 careers. Engineer reinvents herself and propels exploration — without leaving her roots.

Laurie Morrow always knew she didn’t want to live anywhere but her hometown of Houston. That hasn’t stopped her from progressing in her career or enabling a better future for humanity.

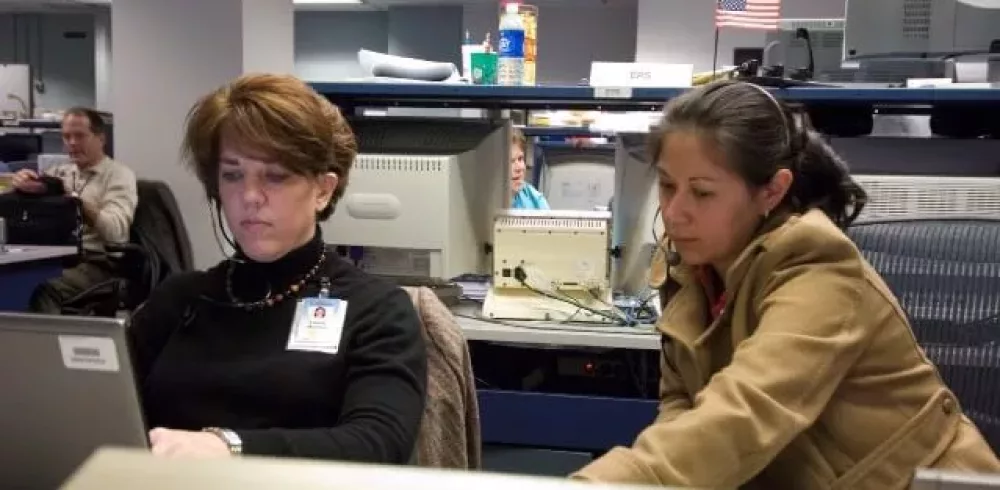

The Boeing engineering manager joined the International Space Station when the program was just getting started. As the ISS and its missions have evolved, so has Morrow’s professional journey.

Morrow has contributed to the ISS through three distinct careers — traveling around the world for her job but always coming home to Texas.

Phase 1: Technical pioneer

After earning a degree in mechanical engineering and working for a NASA contractor, Morrow joined the space station team. She analyzed the passive thermal control system for the space station’s U.S. module, making a lasting impact. That system has helped the ISS withstand extreme temperatures for more than 20 years.

“If the heater patches aren’t exactly in place, condensation forms and leads to corrosion,” Morrow said. “We optimized the heating to ensure the integrity of the module.”

Morrow’s innovations also have brought the world closer. In addition to her work on the U.S. module, Morrow partnered in-country with German, Italian, Swiss and Japanese space agencies. She helped them use the thermal math model she developed to build their sections of the ISS and ensure integration with rest of the space station.

“As the ISS frontrunners, NASA and Boeing guided other countries through development, but we also learned from them,” Morrow said. “That global partnership absolutely matters to this day, because it furthers the good we can do as humans.”

Phase 2: People person

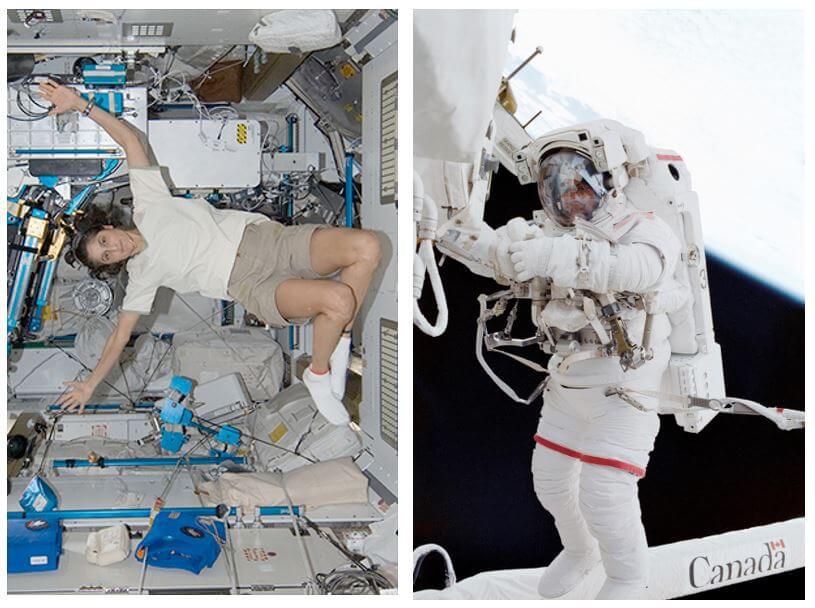

After spending two decades specializing in space station thermal control systems, Morrow narrowed her focus to people on the space station. She spent 10 years in human factors, studying how humans interact with space station hardware and designing accordingly.

Human factors such as maneuverability and visibility vary, for instance, when astronauts are wearing street clothes inside the space station (left) versus suits and gloves on spacewalks (right). Being mindful of human factors helps engineers design with first-time quality. (NASA photos)

Human factors such as maneuverability and visibility vary, for instance, when astronauts are wearing street clothes inside the space station (left) versus suits and gloves on spacewalks (right). Being mindful of human factors helps engineers design with first-time quality. (NASA photos)

“We have to deal with the effects of gravity, both on the astronauts and on our hardware,” she said, noting that with the slightest push on a surface, astronauts need to contort their bodies to stay in place.

Watching her work take flight left an impression. “Launches are always memorable,” Morrow said. “Seeing the hardware you built going up to the space station is very cool. Even just walking through the mock-ups, you think about what the crew is doing and how can we make it better for them?”

Phase 3: Forecaster

Today, as a senior manager of ISS integrated logistics, Morrow draws on her love of math and every professional role she has had to date.

She keeps tabs on space station hardware, working with suppliers and stakeholders to ensure astronauts have what they need on station. Morrow and teammates also predict hardware performance and maintenance needs through advanced modeling and strategic planning. She stressed the importance of the work.

“If a piece of hardware fails on orbit and a spare isn’t available, it could take months or years to get the part back to Earth for repair and back to space again,” Morrow said. “We have to get things right the first time.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News