The extensive expertise in Additive Manufacturing processes at Il Sentiero International Campus (an Industrial Research Centre established by Ecor International and based in Schio, Magreta, and Modena) empowers Ecor International to stand out among the Veneto and Italian aerospace industry excellences with tailor-make solutions for every customer, depending on the specific project and component requirements.

“We begin the process by addressing the customer’s needs, and through our collaboration with Il Sentiero International Campus, we can initiate a tailored research project to evaluate and provide the most sustainable and effective solution.” explains Rinaldo Rigon, Ecor International, Core Processes & Competences Manager.

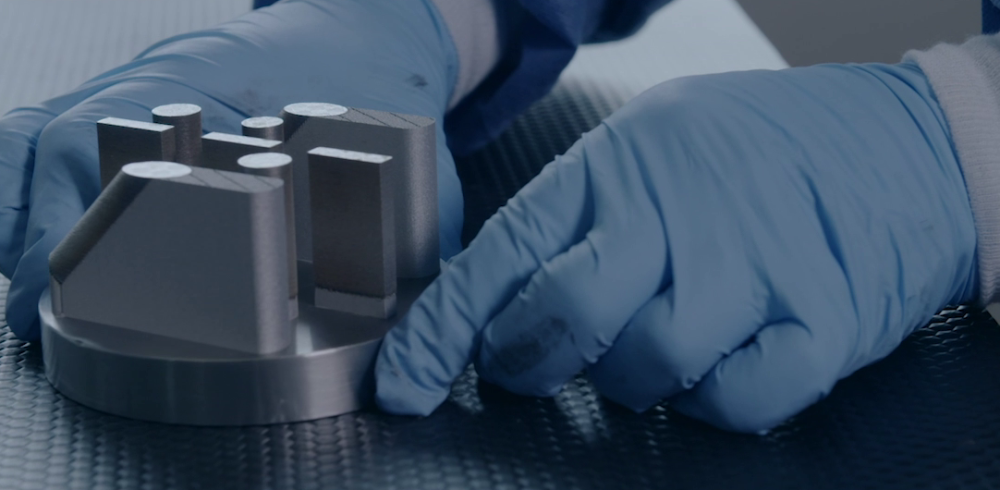

In the production of aeronautical components Il Sentiero International Campus researchers and engineers utilize 3D printing technology to fabricate inspection jigs, which faithfully replicate the parts necessitating specific precautions.

Through the integration of 3D printing into the manufacturing and welding processes, the production of aerospace components is yielding increasingly superior quality outcomes.

Parts produced through additive manufacturing can serve various functions, such as facilitating the alignment of two components for specific welding positions, overseeing free surfaces, and ensuring safe packaging during transport.

- When the components to be welded have a specific angle or orientation, the 3D-printed tool can provide support and ensure the correct positioning during welding.

Even in the case of resistance welding (the specialized process involving the creation of weld spots at millimeter intervals), it is the 3D-printed tools from the research center that guarantee precise targeting.

An example of a critical component that follows these processing steps in Ecor International’s Aerospace department is the fuel tube of the Frecce Tricolori, which requires extremely precise and evenly spaced points.

- In the case of free surfaces, such as parts with irregular shapes that are challenging to manufacture or curved surfaces, 3D printing technology proves invaluable in production. It simplifies the measurement and shape control process even before welding.

This is particularly evident in components for air transfer and cooling in aircraft, which Ecor International produces while ensuring precise fluid-dynamic performance aligned with the unique geometry of these freeform and contoured surfaces.

“The design of the 3D printing process stands as one of our most powerful tools for delivering personalized services to our end customers,” explains Mario Franchi, Il Sentiero International Campus, Additive Manufacturing Laboratories & Technologies Research.

“We manufacture parts that are consistently unique, providing solutions to novel and highly specific requirements. This allows us to offer customized solutions swiftly; with the additive manufacturing process, we can hold in our hands what we’ve designed within just a few days.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News