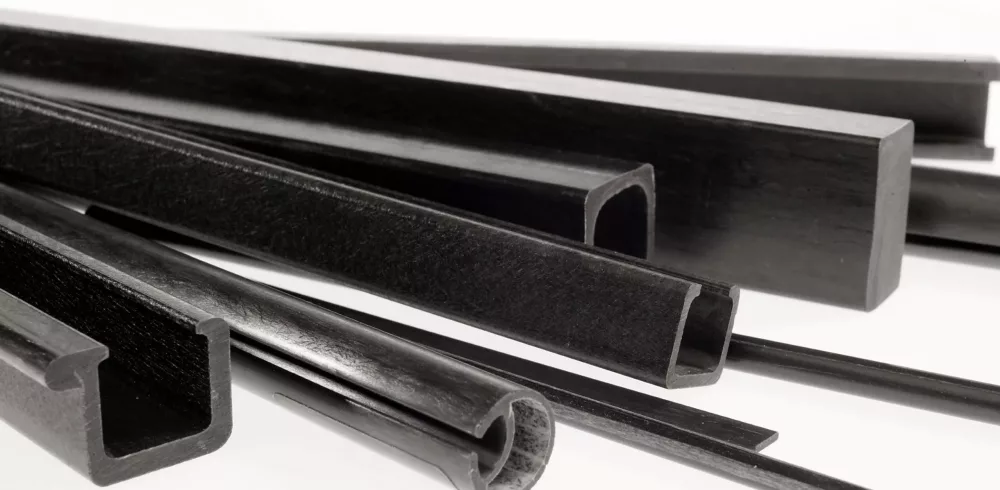

Pultrusion and pull-winding specialist Exel Composites has released a new composite tubes whitepaper that explores some of the key considerations for specifying composite tubes such as mechanical properties, maintenance requirements, performance compared with traditional materials including steel and aluminum, aesthetics and price. The topics covered in the whitepaper include the role of hybrid composites in thin-wall applications and the best manufacturing technique for producing composite tubes with high hoop strength.

Exel Composites has created a guide to design considerations for composite tubes, sharing key details about the requirements for composite tubes in applications such as camera tripods, window cleaning equipment, IMR equipment, medical applications, sporting equipment, telescopic poles, and camouflage support poles. The whitepaper also outlines how pultrusion and pull-winding can be used to create cost effective profiles that meet, and often exceed, requirements in terms of mechanical properties.

“When it comes to industrial tube and pole applications, stiffness and strength requirements have generally favored the use of metals because of their familiarity, good mechanical properties, and relatively low price. However, thanks to the many advantages of composites such as being lightweight, corrosion resistant and more flexible in terms aesthetic possibilities, composite tubes are becoming increasingly popular in different industries,” explained Lauri Turunen, Product Business Owner for tubes and telescoping poles at Exel Composites.

“Just as with the range of metal alloys historically available, composites come in different types, such as fiberglass and carbon fiber, and can be manufactured in numerous ways, using pultrusion, filament winding, or pull-winding. However, not all composite tubes are designed equal and, when looking to replace a metal tube with a composite one, it is important to select the right tube for the job”, concluded Turunen.

Even with knowledge of the benefits, switching from metals to composites might seem like a daunting task given the abundance of available options and limited industry-wide experience of using composites for certain applications. This challenge can be overcome by working with a knowledgeable composites partner, such as Exel Composites, who understands all these considerations and possible reservations and can propose the most suitable solution available.

To find out more about the design considerations for bespoke composite tubes, visit Exel Composites’ website today to download the whitepaper: https://exel.pub/40dYqhy

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News