Big Motoring World, one of the UK’s leading independent pre-owned car dealers, is using the TreadReader 3D DriveOver ramp system to improve productivity and efficiency at its national preparation centre in Peterborough.

The company invested £14million in the new facility to provide ongoing support for the Group’s fast-expanding UK dealership network. The centre is equipped with a full production line including 70 ramps for maintenance and inspection work and 15 MOT bays, where pre-delivery vehicles and tyre inspections are carried out.

“We prepare over 200 cars a day at the Peterborough centre,” says Operations Director, Bob Ruprah, “and the TreadReader DriveOver ramps have proved to be a game-changer when it comes to taking fast and accurate tyre tread readings.”

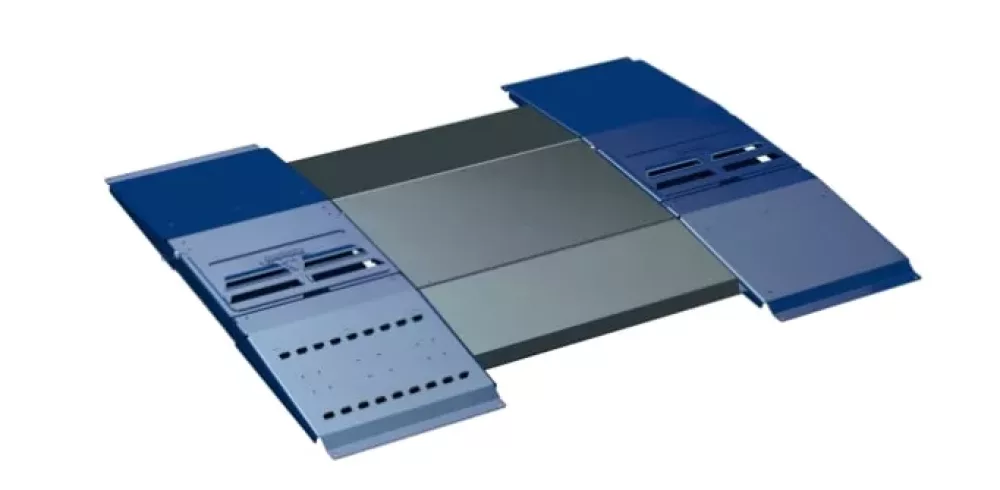

Four TreadReader DriveOver ramps are installed: three collect tyre tread data as each car enters the initial preparation phase and the fourth provides a double check to capture precise tread readings which are automatically entered into each vehicle’s online details.

The surface-mounted system measures each tyre as it passes over a pressure switch, and key tyre data is then posted to the parts department for replacement tyres to be ordered and prepared ahead of the vehicle arriving at the finishing bay.

Then, the tyre tread depth and description is posted to the Big Motoring World website, along with the car’s general details, so prospective customers can see the exact condition of each individual tyre.

“This is all about speed and accuracy,” says Bob. “We have a one hour window in which we need to record the condition of each tyre and place any requisite tyre orders with our parts department for fitting, prior to the vehicle entering the workshop.”

Bob explains that before installing the DriveOver ramps, the process was manual, which took twice as long to complete, involved paperwork and could lead to human error and delays.

“Now, we simply drive each vehicle over the ramp and all tread depths are instantly scanned and recorded with 100% accuracy, while tyre orders are internally placed using the API.”

The tyre data is processed by the TreadReader software which analyses each scan, calculating tread depth and displaying 3D renders of the actual tyre tread pattern, with colour-coded tread depth measurements. Information from the TreadReader software is then uploaded in seconds to the TreadManager online reporting suite (or other data management system).

Each 3D scan uses 320,000 measurements points with accuracy to within 0.2mm. “By scanning the full width of the tyre and 50-60mm around it, the system far exceeds the accuracy, consistency and repeatability of traditional dip gauges and non-contact ‘laser pointers’,” adds Bob.

Furthermore, says Bob the accuracy and reliability of the technology, provides an increased general awareness of tyre conditions, while reducing potential accidents and reducing daily workshop costs

“Ultimately, the TreadReader system is designed to improve customer understanding and road safety,” says TreadReader Area Sales Manager for the UK and Ireland, Richard Crummack. “For example, the average stopping distance on tyres with below 3.5mm of tread will be significantly increased and at the legal minimum of 1.6mm, the distance can be up to 65% greater.”

Plus, explains Richard, low tread depth will significantly increase the risk of aquaplaning: on tyres with less than the minimum tread depth, protection against aquaplaning is reduced by around 40%. “TreadReader helps guard against these issues and enables tyre technicians to provide fast and accurate information to keep road users safe and legal.”

“Safety is paramount,” adds Bob Ruprah, “and in this regard, the TreadReader DriveOver system ensures best practice, workshop efficiency and quality assurance for our customers.”

Operating from 11 locations in the UK, Big Motoring World carries an average stock of over 6,000 vehicles for outright purchase, finance or part-exchange. Industry accreditations include Used Car Supermarket of the Year and Dealer Website of the Year.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News