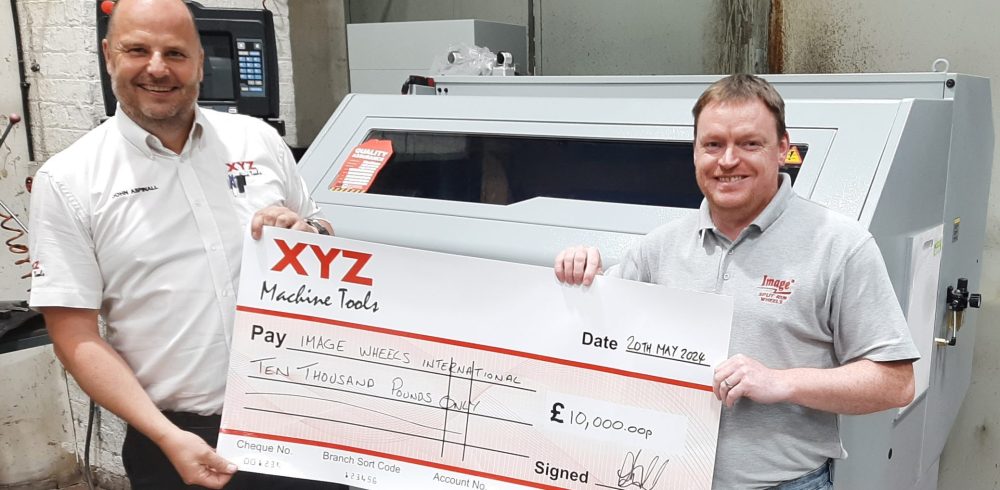

Tipton-based Image Wheels has emerged victorious in a prestigious competition hosted by XYZ Machine Tools at the recent MACH 2024 exhibition. The company received a generous £10,000 (plus VAT) discount on the purchase price of any new CNC machine in the XYZ range. This forward-thinking manufacturing business opted for a brand new Proturn RLX 555 gap-bed lathe with ProtoTRAK® control, aiming to boost capacity and counteract the current skills shortage.

Founded in 1987, Image Wheels is now a leading UK manufacturer of alloy wheels to customers worldwide. The family-owned business produces both classic and modern high-grade alloy wheels to order, supplying over 50 styles in sizes ranging from 10-20” in diameter, with customisable widths and offsets. Applications include race cars, dragsters, classic cars, kit cars, trikes and offroad vehicles of diverse types. Keeping pace with the company’s busy order book requires ongoing investment in the latest manufacturing technologies. However, there is a notable industry challenge to navigate.

“Finding CNC programmers, setters and operators who can hit the ground running is very difficult,” reveals Jason Worrall, Works Director at Image Wheels. “Instead, we are gradually upskilling our existing manual machine operators. We can make this task easier by tapping into the ease-of-use that comes with the ProtoTRAK® control.”

Jason’s visit to MACH 2024 marked his first time at the exhibition, where he visited several stands to assess potential CNC turning machines.

“I didn’t know about the competition to win a £10,000 discount on any XYZ machine until I got to their stand,” he says. “I filled out an entry form there and then. XYZ’s Area Sales Manager John Aspinall, who was familiar to us, phoned me a few days after the show and I could tell by the excitement in his voice that I had won. It was a great feeling.”

The discount was applied to the popular Proturn RLX 555 gap-bed lathe, chosen for its sizable turning capacity, impressive versatility and user-friendly ProtoTRAK® control. The machine is already in situ at the company’s Tipton manufacturing facility.

“We only really have one machine for producing large 20” diameter wheels, so with the RLX 555 we’ve effectively doubled our capacity for this type of work,” explains Jason. “Although it’s our first XYZ machine, we employed a new operator at the back end of 2023 who has a lot of experience with ProtoTRAK®, which means we can get the RLX 555 cutting metal and earning money straight away. At the same time, we’ll train one of our existing manual machine operators on the ProtoTRAK®. This strategy will help us negate the current lack of experienced CNC operators.”

Proturn lathes with the RLX 15.6” touchscreen ProtoTRAK® control are ideal for one-off and low-volume production. As the simplest control on the market, machine shops can be making parts profitably in no time. Even an operator with no previous CNC experience will be producing complex parts within hours.

The new XYZ Proturn RLX 555 will machine alloy wheels from castings, performing a range of turning, boring and profiling operations. Image Wheels produces its products from high-grade cast aluminium, typically in batches of two or four, and sometimes up to 20-off for a race team. The company, accredited to ISO 9001:2015, has manufactured components for record-breaking and championship-winning cars all over the world.

Proturn RLX 555 machines offer a swing-over-bed of 560mm, a spindle bore of 104mm and come with a 315mm three-jaw chuck as standard. Image Wheels opted for the 1m bed version, though the Proturn RLX 555 is also available in a 1.75m model. The machine supplied to Image Wheels includes numerous advanced options, including the DXF File Converter.

“Rather than using dimensioned drawings with complex profiles, we can simply output a DXF file, upload it into the machine, select the contour and away we go,” says Jason. “It will accelerate our process and ensure less opportunity for error.”

Quality is paramount at this progressive manufacturing business. Image Wheels manufactures its products in accordance with British Standards, including BSAU 50 Part 2 Section 5C, BS ISO 4000-2 and BS ISO 16833. The company is a member of the British Standards Institute, and all wheel designs undergo tests by an independent company using FEA (finite element analysis).

“Our main differentiator is our products, particularly their quality,” concludes Jason. “There are very few alloy wheel manufacturers worldwide who can compete in the same way. Sure enough, all of us in this industry have business challenges to overcome, with skills proving one of the most prominent. However, with a bit of fortune that arrived by winning the XYZ competition at MACH, we’ve found the perfect way forward.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News