CRP USA Attended AMUG 2019 as Speaker

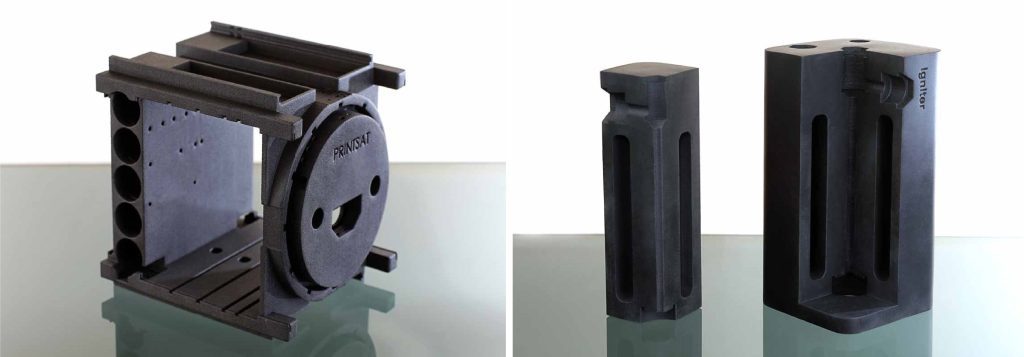

CRP USA will be attending Additive Manufacturing Users Group (AMUG) as speaker. The 31st edition of AMUG will be held from 31st March to 4th April, 2019, at the Hilton Chicago, in Chicago, Illinois. At the 2019 edition Stewart Davis will be presenting the paper: “Construction of CubeSatellite used to dispense TubeSatellites using Additive Manufacturing”. The speech is set for 1st April, 2PM, at the International Ballroom, Hilton Chicago, in the track: “Aerospace/Transportation”. Stewart Davis will explain how the use of Windform composite materials, originally developed for the Motorsports industry by CRP Technology, is now finding many uses in space exploration. Mr. Davis will also demonstrate the effectiveness of additive manufacturing and the use of Windform as a structural material for space applications. Hightlighted at AMUG will be the case study that follows the successful construction and launch of the TuPod. CRP USA works alongside key space industry leaders. Based in Mooresville, North Carolina, CRP USA employs a highly skilled staff that specializes in the manufacturing and creation of end-use parts and prototypes built from Windform high performance composite materials for LS technology. With new projects and new developing perspectives in the field of AM, CRP USA has been the technological partner of space applications such as the construction of a CubeSat in additive manufacturing, gathering the interest of the most important bodies involved in space engineering. Additive Manufacturing Users Group (AMUG) Conference brings together engineers, designers, managers, and educators from around the world to share expertise, best practices, challenges, and application developments in additive manufacturing. AMUG is a global community focused on accelerating the education and advancement of additive manufacturing and 3D Printing.

Robinson Manufacturing Acquires National Hickman’s Joist Manufacturing Business

Having recently announced our intention to invest in a major expansion of iBeam manufacturing capacity in the West Midlands by opening a new factory in Willenhall, we are delighted to confirm that Robinson Manufacturing Ltd (RML) has instead acquired the joist manufacturing business of National Hickman from Hickman Industries Limited. This major expansion, which includes both the Wolverhampton and Fife factories, takes the number of factories in the Robinson Manufacturing group to seven across the UK and facilitates our commitment to support a variety of regional and national housebuilders who have requested additional supply in these areas. CEO of Robinson Manufacturing, Simon Kidney, is delighted by the running start the acquisition gives the business: “We have been in personal communication with senior teams within housebuilders of all sizes over the last three months and they are crying out for additional joist capacity across the West Midlands and beyond,” he explained. “Acquiring this joist business allows us to start to meet the scale of demand from day one – as well as making Robinson Manufacturing a truly national business.” As well as adding substantially to joist manufacturing capacity, the Wolverhampton factory comes with substantial office space, which RML will use to concentrate our floor design into a new centre of excellence, mirroring our highly effective truss design structure in Wellingborough. The successful Robinson Manufacturing customer service model, which has underpinned the company’s significant growth in recent years, will also be applied to housebuilders choosing RML for joist supply. The reputation of Robinson Manufacturing is built upon the personal commitment of our outstanding people, many of whom have grown with the company since its beginnings as a family business. As we expand further, we continue to invest in local communities allowing us to attract the finest talent in the areas we serve across the country. This dedication to customer satisfaction, open communication and quality is unrivalled and enables us to supply competitively at every level in the housebuilding sector. Robinson Manufacturing continues to build partnerships with housebuilders from the smallest local operation to the best-known household names through national contracts.

Succession Planning & the Skills Mix For Manufacturers Event

Succession Planning & the Skills Mix For Manufacturers Event : Two key themes regarding the future of manufacturing are access to appropriate technology and how to develop a team with the appropriate skills to meet the current and future needs of the business – including team members who have grown up with advanced technology and want to use it to drive innovation and product ability improvements within businesses. Hear from a range of speakers about how they have addressed the skills challenge and from a range of skills/training providers and how they can help. This event will be held in collaboration with the West Yorkshire Consortium of Colleges ‘The Skills Service.’ Speakers: Andrew Wright (Reliance Precision)Marie-Claire Micuta (University of Huddersfield)Julie Penman (NPL)Richard Burguete (NPL)Jas Hayre (WYCC)TBA (Cummins) Ahead of this event, NPL’s Product Verification team are offering two one-hour training sessions, one on Micrometers and another on Calipers. Both sessions will take place at 3:30 and 4:30pm alternatively, providing the opportunity to attend both sessions. Please note registration is essential for these training sessions and places are limited. To register your interest, please tick the box ‘Are you interested in training sessions ahead of the event?’ when signing up, so we can contact you. Parking will be available on a first come first serve basis from 5:15pm onwards Complimentary food and drink will also be available. National Physical Laboratory3M Buckley Innovation CentreFirth StreetHuddersfieldWest YorkshireHD1 3BD Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Wenzel Group Celebrates Record Installation

The Wenzel Group is celebrating following the installation of its landmark 9000th high-tech measuring machine. Designed and manufactured by Wenzel, the product follows another important milestone in the German metrology specialist’s history, with the firm also recently commemorating its 50th year in the business. The installation of the WENZEL LH 1512 3D Coordinate Measuring Machine (CMM) coincides with a record-breaking output of almost €92 million for the company in 2018, with strong sales success across its four regions DACH, EMEA, Asia and America. The CMM purchase also comes full circle with Wenzel’s prestigious history, with the very first measuring machine sold in Austria and now its 9000th going to another firm in the region, voestalpine Krems GmbH. With growth expected over the next few years, the record-breaking sale is exemplary of the German firm’s strong position in the metrology market, as well as a mark of how measurement products are heading into the digital era. Lauding the landmark installation and prosperity across the region, Dr. Heike Wenzel, managing partner of Wenzel Group GmbH & Co. KG, said: “In 1981, the very first measuring machine built by Wenzel was sold by GGW Gruber in Austria. Now, the 9000th machine manufactured in the German factory with the serial number 189000 has also gone to Austria. That cannot be a coincidence.” Installed at the Krems site in Austria, the decision to purchase the WENZEL LH 1512 3D Coordinate Measuring Machine by voestalpine means the firm can streamline its operations across the automotive, construction, energy and wine & fruit sectors with high levels of performance and accuracy. Like all Wenzel machinery, the new CMM has been engineered from granite to eliminate heat sensitivity and increase precision within its new environment. The low cost of ownership, as well as the optimal price-performance ratio of the WENZEL CMM, were also core motivating factors behind the purchase of the 18-tonne machine by the Austrian technology specialist. Renowned for its precision, the LH 3D CMM is the latest in high performance, bridge-style technology. Its long-term mechanical accuracy and ergonomic design, along with sensor choices to suit a wide range of applications, means the machine is ideally suited for situations which require high throughput. The WENZEL LH 1512’s gantry design caters to this requirement and is specifically designed for the inspection of large-volume and heavy workpieces.

NPL Manufacturer Measurement Network Event

NPL Manufacturer Measurement Network Event : Succession Planning & the Skills Mix for Manufacturers event is focusing on two key themes regarding the future of manufacturing are access to appropriate technology and how to develop a team with the appropriate skills to meet the current and future needs of the business – including team members who have grown up with advanced technology and want to use it to drive innovation and product ability improvements within businesses. Hear from a range of speakers about how they have addressed the skills challenge and from a range of skills/training providers and how they can help. The event will be held in collaboration with The Skills Service, which is part of the West Yorkshire Consortium of Colleges. Parking will be available on a first-come, first-served basis from 17:15 onwards and complimentary food and drink will also be available. The National Physical Laboratory (NPL) established a Northern hub with the aim of supporting regional manufacturing SMEs to help them to achieve their full potential to become competitive within a challenging worldwide market. NPL will offer its extensive expertise in measurement and product verification related services to help SME Manufacturers to identify appropriate validation methods within their business with the aim of increasing efficiency, reducing waste and improving product quality. The NPL Manufacturer Measurement Network has been created to make this process as simple and seamless as possible – with two levels of membership available. The aim of the Network is to enable the members to benefit from NPL’s expertise with the view of optimising productivity and increasing confidence in their products, keeping their businesses at the forefront of measurement and validation technology. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

German Manufacturer Moves Headquarters to East Midlands

German manufacturer Wenzel Metrology UK has moved its headquarters to the East Midlands as part of a wider strategy to drive growth. The manufacturer moved into a period property as part of the switch, which allows the firm to better serve its existing national client base, as well expand its operations across the region. A crucial component to the firm’s future growth, the new offices in Sandiacre are nestled between Nottingham and Derby. The firm looks to add to its stellar customer base, which includes renowned brands such as Rolls Royce, Bentley and Magellan Aerospace. Wenzel Metrology is a world leader in coordinate measuring technology, providing highly accurate measurement equipment across a wide variety of industries, including automotive, aerospace, power generation and medical technology. Its machines, which have an install base of more than 10,000 worldwide, are used to provide highly accurate measurements of specialist equipment, including aero engines, car bodies and medical joints. “It’s great to be here in the East Midlands. The new location opens up a wealth of opportunity not only in terms of our existing clients but also for expanding our operations across the country with our top engineering talent. This is a company with more than 50 years’ experience in providing highly accurate metrology solutions to some of the biggest brands in the world, so we can’t wait to let even more people know of the quality offered by Wenzel machinery,” commented on the move Steve Hughes, managing director of Wenzel Metrology UK. Wenzel Metrology is a global leader in innovative metrology solutions, with subsidiaries and agents in more than 50 countries.

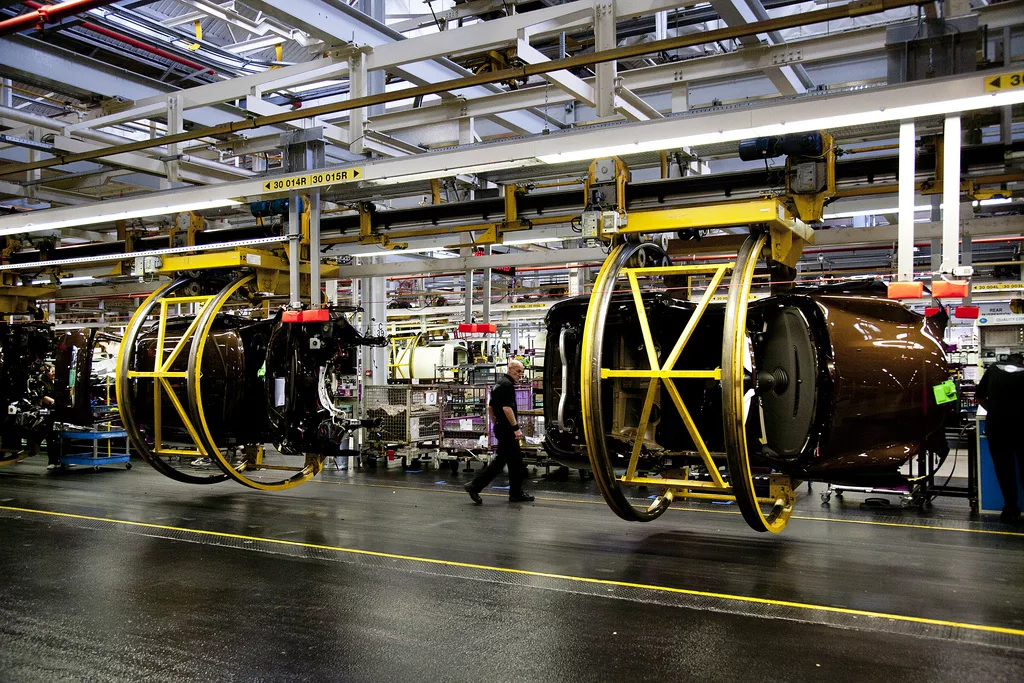

Brexit and the UK Automotive Industry

Brexit and the UK Automotive Industry : Uncertainty around the final Brexit deal between the UK and the EU still remains. This is particularly true for the automotive industry where OEMs such as Ford, Honda and Renault-Nissan have all publicly raised their concerns. To find out what was happening within the industry, OpenText and the Centre of Brexit Studies conducted a comprehensive study focusing on this sector. The research study set out to identify the likely implications that different Brexit options could have on the industry and how prepared organisations were across five key business areas: supply chain management, operations and logistics, human resource management, regulations and compliance, and customer communications. The research drew on many different information resources and included in-depth interviews with senior executives in the UK automotive industry. The research findings suggest that all current available trade scenarios put up different types of trade barriers for the sector, and makes a series of recommendations for risk management and scenario planning strategies that can help companies adapt, whatever the final outcome of Brexit negotiations. Key recommendations include: Automotive companies need to have good enterprise information management (EIM) policies in place for managing and reporting on contracts to implement changes and mitigate risks. OEMs and suppliers need to have a strong information governance strategy in place to ensure compliance with any new regulatory requirements or checks. More emphasis on workforce planning and skills development is needed for the UK automotive industry to mitigate restrictions or changes to the free movement of people. Closer communication and collaboration between automotive manufacturers, partners and customers is needed to ensure a free flow of information. Automotive manufacturers need to have an improved understanding of their supply chain, particularly with respect to any new documentation and compliance requirements that might be put in place. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

The Winners of Made in Central & East England Awards

Made in Central & East England Awards has announced its winners and amongst them are a sports car manufacturer, a flatbread producer and a developer of medical-grade cases for iPhones and iPads. The ceremony, which took place at the Jurys Inn Milton Keynes, celebrated the region’s manufacturing prowess, with all winners set to complete on a national scale at Insider‘s Made in the UK 2019 event in Coventry in June. Sponsors for the evening were Grant Thornton UK LLP and Howes Percival, while HSBC UK sponsored the drinks reception. Digital Engineering/Technology AwardWinner: OALOAL is using robotics and digital technologies to transform food production. It was handed the award for its desire to create jobs and export opportunities.Shortlisted:FlexEnableAcuigenHuxley Bertram Engineering LtdBulgin Automotive AwardWinner: Radical Sportscars LtdRadical manages its research and development in-house and is an advocate of using advanced lightweight structures and powertrains in its models.Shortlisted:CharpakMilton Keynes PressingsBroadways Stampings Ltd Manufacturing Innovation AwardSponsored by Grant Thornton UK LLPWinner: FutureNovaThe company, which designs medical-grade accessories for iPads and iPhones, was founded just four years and has set its sights on a £12m turnover by 2020.Shortlisted:Ion SciencePeck DrinksFords Packaging Systems LtdGo GlassVIP PolymersOrbital Fabrications Apprentice of the Year AwardWinner: Kyle Constable of OALKyle is currently completing a higher apprenticeship in food and drink manufacturing operations management at the University of Lincoln. He was awarded for his “ongoing unwavering commitment to his personal development”.Shortlisted:Will Vanner of Prestige Homeseeker Park & Leisure HomesLoren Cooper of Prestige Homeseeker Park & Leisure Homes Export AwardWinner: Beardow & Adams (Adhesives) LtdThe business has a “clear commitment” to growing exports, according to the judges, and sells more than 80 per cent of its products overseas.Shortlisted:Peter BrotherhoodRadical Sportscars LtdSuperyacht Tenders and ToysVIP PolymersIon Science Food & Drink AwardWinner: Fairfields Farm CrispsFairfields supplies Tesco stores across the UK and recently signed a deal to supply Ocado.Shortlisted:Premier Foods UKPeck DrinksSignature FlatbreadsEastern Country FoodsPioneer Foods Manufacturing Apprenticeship/Training Scheme AwardWinner: Stainless MetalcraftThe company has been named as one of the UK’s Top 100 Apprentice Employers for two consecutive years.Shortlisted:Prestige Homeseeker Park & Leisure HomesOALRadical Sportscars Ltd Manufacturer of the Year (under £25m)Sponsored by Howes PercivalWinner: Broadways Stampings LtdBroadways has a diverse customer base and its technology, culture and disciplines gives the company a distinct advantage in winning new contracts.Shortlisted:Hansford SensorsMaximum Precision Manufacturer of the Year (over £25m)Winner: Signature FlatbreadsSignature has committed to making significant investments to boost productivity over the next 12 months.Shortlisted:IpecoBeardow & Adams (Adhesives) Ltd Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

The Integration of Energy-Efficient and IIoT Capabilities

The chemicals industry in Europe is in the midst of a huge transformation with manufacturers looking to redefine their value proposition and explore new business models. Encouraged by the gradual recovery of oil prices, chemical manufacturers are increasing their demand for centrifugal and positive displacement (PD) pumps. Plus, the European Commission’s directive to industries to reduce energy consumption is creating a fertile market for smart, intuitive, Industrial Internet of Things (IIoT)-enabled pumps with asset monitoring features. The total pumps market in Europe generated estimated revenue of $1,334.7 million from the chemical industry in 2018. Centrifugal pumps used in the chemical processing plants represented 75.6% of the total pump market, and the remaining 24.4% of the market was held by positive displacement (PD) pumps in 2018. The compound annual growth rate for the total market is an expected 2.0% through 2025. “Pump manufacturers offering value-added services such as end-to-end monitoring of pump performance throughout their lifecycle to increase energy efficiencies will remain competitive,” said Kiravani Emani, Industry Analyst, Industrial team at Frost & Sullivan. “Furthermore, the shift towards digital chemical plants will create opportunities for pumps embedded with connectivity and intelligence capabilities, as they can aid predictive maintenance, reduce asset failure and, consequently, prevent the shutdown of plants.” Frost & Sullivan’s recent analysis, European Pumps Market in the Chemical Industry, Forecast to 2025, evaluates the various types of centrifugal and PD pumps that are used in the chemical processing industry. It includes detailed assessments of pump adoption across sub-industries such as basic, specialty, agro, and consumer chemicals. It evaluates the opportunities across Germany, France, Italy, the UK, Scandinavia, Iberia, Benelux, Eastern Europe, and the rest of Western Europe. It also includes technology perspectives and the role of IIoT in the pumps market.

Europac3D Showcases at Manufacturing & Electronics Show

Europac3D, one of the UK’s leading 3D printing, scanning and inspection businesses, will be showcasing some of the latest innovations in 3D printing and scanning at this year’s Southern Manufacturing & Electronics Show at Farnborough International Exhibition and Conference Centre, 5th – 7th February, Stand G80. The company will be showcasing the following innovations at their stand: ROBOZE: Europac3D will be exhibiting Roboze 3D printers at this year’s show – the very first showing of these printers in the UK. Europac will be providing visitors with a unique opportunity to see one of the only FDM 3D printers capable of producing parts in engineering grade high performance thermoplastics, including the highly sought after PEEK and ULTEM. DWS: Also making their UK debut at this year’s show are DWS’ range of SLA 3D printers. Specialising in dental, jewellery and industrial applications, the DWS SLA printers have over 75 different materials options including direct casting, high temperature, ultra-high definition clear and flexible rubber parts. ARTEC LEO: Europac3D will be proudly showcasing live demonstrations of the much anticipated Artec Leo handheld 3D scanner. Leo is the first ever scanner to offer complete onboard automatic processing without the need to be tethered to a computer. “We are delighted to be offering visitors to this year’s show the opportunity to experience the first ever chance to see of a number of innovative 3D printing and scanning technologies first-hand. Our team will be on hand to answer any questions and to provide expert advice. We will also be providing live demonstrations to showcase the capabilities of our machineries and software, so we look forward to welcoming customers to our stand for what promises to be an action-packed experience,” commented John Beckett, Managing Director of Europac. Europac 3D, headquartered in state of the art facilities in Crewe, Cheshire, has more than 20 years of experience in the field of 3D scanning, printing and installation serving a range of sectors and more than 500 businesses across the UK. The company offers a full spectrum of services from the supply of cutting-edge scanners, printers and accessories to installation, maintenance and training of staff in the usage of 3D hardware and software.