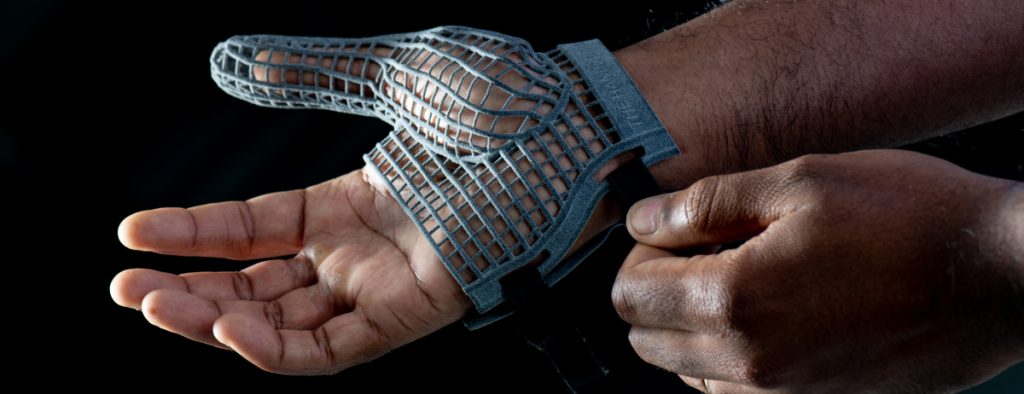

Land Rover Engineers Developing 3D-Printed Glove

Land Rover Engineers Developing 3D-Printed Glove : Engineers from Jaguar Land Rover are working on a lightweight 3D-printed glove that could help better protect employees from the threat of a musculoskeletal disorder. The glove is designed for people working on the production line, such as those required to fit clips or fasteners into the chassis during assembly of JLR’s luxury vehicles. “The health and wellbeing of our workforce remains our priority across all factories and facilities. Technologies like the 3D-printed glove allow us to use the world-leading expertise and equipment we have in-house to protect the hands of our makers, developing equipment that will make Jaguar Land Rover a great place to work, now and in the future,” said additive manufacturing strategic engineer Chris Noble. Engineers at JLR’s Gaydon site, which is home to one of the largest 3D printing facilities in the UK, are using the company’s advanced manufacturing expertise to design and 3D print a lattice-style structure which would provide support to reduce muscle fatigue, but also be flexible and comfortable enough to wear during an eight-hour shift. In the short term the gloves will support workers across JLR’s facilities, helping to protect against musculoskeletal disorders. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News Manufacturing & Engineering Magazine (MEM), is a the leading UK based monthly print & digital publication focused on promoting innovation in manufacturing and engineering available here in the UK. We cover : SUSTAINABILITY (Waste & Water Management, Recycling, Energy); INMOTION (Rail, Marine, Aerospace, Automotive, Defence); INFRASTRUCTURE (Oil & Gas, Nuclear, Construction); Healthcare (Medical), TECHNOLOGY(Printed, Connected, Software, Composite); MANUFACTURING (Chemical, Metals, Plastics, Electronics, Electrical); CONSUMER GOODS(Furniture, Electrical, Electronics, Food) to name but a few. We have over 50,000 views of each issue of MEM on average in 2022 and go to print monthly and also publish in our newsletter, (each issue is available free for 12 months digitally). Our focus is aligned across the next 12 months with our global media partnerships around Trade Events and also contains original content.

Kubota Has Unveiled Its New KX080-4a2 Midi Excavator

Kubota, a leading manufacturer of construction machinery, has announced the launch of the KX080-4a2 as the latest in its range of midi excavators. This new machine is capable of the same reliable performance as previous models but includes Kubota’s V3307 direct injection engine – which is now fully Stage-V compliant. The new model has a reduced engine RPM DPF re-gen, giving reduced noise levels, increased DPF re-gen intervals and increased DPF replacement life. This reduces maintenance costs and the machine’s environmental impact whilst enhancing productivity for a wide range of tasks. The KX080-4a2 incorporates a brand new 2-pump load-sensing hydraulic system which ensures smoother operations when using front attachments, regardless of loading size. By allowing hydraulic oil to flow according to the specific range of the operator’s lever motion, the new system reduces fuel consumption and improves the overall operating performance. The machine’s auto idling system is fitted as standard – reducing not only running costs but noise and exhaust emissions, enabling users to operate in a wider range of environments. What’s more, vital components such as the battery, fluid tanks and filters are now easier to access, making maintenance simpler than ever. Numerous safety features come as standard on the KX080-4a2; such as the auto-stop function on the tank’s electric refuelling pump, an anti-drop valve on the boom and arm cylinder, advanced visibility mirrors, a seat belt indicator and increased stability. The machine is protected by Kubota’s highly regarded anti-theft system, meaning only programmed keys will enable the engine to start up. Anyone attempting to start with an un-programmed key will activate the alarm. Newly enhanced features send an alert to remind the operator to extract the key after operation, and an LED to alert potential thieves that the system is activated. The updated excavator – which is a compact width of 2,200mm comes with a floating dozer blade fitted as standard. This model has been designed with improved operator comfort, including a more spacious cab, improved foot space, including a re-designed foot pedals and deluxe high-back suspension seat. The cab features an air conditioning unit and an easy-to-read LCD panel so users can monitor the machine’s status at all times, The machine can also be equipped with a two-piece boom. This feature’s user-friendly design makes operation simple whilst its innovative hydraulic mechanism enables smooth operation. Users benefit from expanded working range, impressive dumping range and the ability to operate in narrow spaces. Glen Hampson, Business Development Manager, Construction Division, Kubota UK, comments: “We are delighted to be unveiling our latest midi excavator. At Kubota, our customers and their needs are at the heart of every one of our products and the KX080-4a2 is no exception. Offering a market leading performance with improved comfort and lower maintenance costs, this newest addition to our fleet will enhance convenience and boost productivity for users, without compromising on Kubota’s well-renowned reliability. It will also aid compliance with the latest environmental and industry standards, making it the ideal excavator for a range of different jobs and environments.” Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Vivalda Announces Investment in Automated Routing Technology

Vivalda Group has announced a new investment of £150,000 in automated routing technology. This funding reaffirms the business’ long-term commitment to UK manufacturing and the growing importance of off-site fabrication within the construction sector. The commissioning of two Radecal ATC CNC Piranha routers at its Birmingham branch enables the company to fulfill the growing demand for non-flammable architectural panels and boards to be cut to size and prepared for delivery on-site. “Increasingly, architects are specifying the use of hidden fixings on non-flammable facades to improve the aesthetics of their buildings. This, along with the more widespread adoption of just-in-time, offsite fabrication has prompted this investment in technology. Automation is increasingly important within the construction sector, as it reduces delivery times, cuts down on transport costs and also eliminates damage and costly mistakes during the fabrication stage,” said Chairman and founder of Vivalda, Peter Johnson. “This investment brings our total number of automated CNC routers to six, demonstrating our commitment to our value-add strategy. Our success is based on the ability to provide architects and contractors with complete solutions – delivering pre-cut, fully prepared cladding boards on-site. This sounds simple in theory, but in practice requires a vision, which is backed up by a commitment to technology investment, manufacturing, logistics, planning and skills.” “I am convinced the success of the UK building industry must be based on improving our skills, increasing our investment in automation and adopting more efficient supply chain models such as modular construction. Our long-term investment in plant, logistics, premises and technology is testament to that strategy,” Peter Johnson added. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Dassault Systèmes Partners with Advanced Manufacturing Research Centre

Dassault Systèmes has announced that it has become a member of the Advanced Manufacturing Research Centre (AMRC) in Sheffield, to support the UK manufacturing industry as it embraces automation, robotics and visualisation at all levels. The AMRC, part of the High Value Manufacturing Catapult, is a world-class research centre for advanced manufacturing, developing sustainable solutions to improve UK productivity, talent and skills. By introducing new ways of automatically assembling complex products and using advanced technologies such as robotics, augmented reality and large-volume metrology, the AMRC addresses the key operational challenges its partners face as they develop the factories of the future through digital transformation. Séverine Trouillet, Global Affairs Director, EuroNorth at Dassault Systèmes said: “We strongly believe that we have entered the Industry Renaissance, a new era where experience will be at the heart of everything we do, from the way we innovate to the way we produce goods. The tools of the Fourth Industrial Revolution, whether automation, robotics or visualisation, are the basis on which we are building a radically new world where entire sectors will be turned upside down. No industry will be transformed quite as much as manufacturing, which is why we are proud to be joining the AMRC and helping its members adopt a digital-first way of thinking, but also create the Future of Manufacturing at the heart of the industrial North.” As part of its AMRC membership, Dassault Systèmes will work closely with UK manufacturers to help deliver the Made Smarter Commission’s goal of transforming manufacturing through the adoption of digital industrial technologies. Working with the AMRC, Dassault Systèmes will help manufacturing maximise the benefits of virtualisation and modeling technologies to innovate faster, improve public–private collaboration and become sustainability champions in the UK. Last year, Corporate Knights – the gold standard for sustainability analysis – ranked Dassault Systèmes No. 1 among the top 100 most sustainable companies in the world. The ranking recognised Dassault Systèmes’ holistic sustainability strategy, from reducing its environmental footprint, to developing the workforce of the future and driving the definition of new business models in today’s Industrial Renaissance. Dassault Systèmes will also support UK industry as it tackles business transformation challenges, whilst turning the UK into the most innovative economy in the world through the use of game-changing technology. To celebrate its membership, Dassault Systèmes will also be engaged in a Made Smarter initiative, recently launched at the AMRC, to create an open-access Smart Factory test bed, which will allow companies to improve their productivity, reduce defects and time to market. Commenting on the news, Rab Scott, Head of Digital at the AMRC said: “British manufacturing has a track record of being among the most innovative and inventive in the world; it was the home of the First Industrial Revolution and it aspires to be the home of the Fourth Industrial Revolution. With Dassault Systèmes as a Tier 1 partner, the AMRC is ideally placed to deliver the sustainable step-changes in productivity that the UK economy desperately needs. Its suite of digital technologies strengthens the AMRC’s portfolio of advanced manufacturing capabilities and puts us in the forefront of Industry 4.0 research and development.” As the innovation hub of the Northern Powerhouse, the AMRC will work with Dassault Systèmes to help the industry prepare the workers of tomorrow. By anticipating the roles required for the future, and by digitally capturing the expertise of retiring engineers, it will be possible to minimise the risk an ageing workforce poses to the UK economy, ensuring that the manufacturing memory of its industrial base is not lost. This will allow for the continuity of innovation in the engineering process, whilst providing a platform for new roles to emerge in a world where information, innovation and production all benefit from the combined access to real and virtual worlds. A strong supporter of British innovation and knowledge sharing, Dassault Systèmes has been involved with the High Value Manufacturing Catapult’s National Composites Centre (NCC) for a number of years. It has helped develop new methods and technologies that have turned the centre into the UK’s hub for design and rapid manufacturing of high quality composite products. Leveraging the learning from its involvement with the NCC and the Bristol & Bath Science Park, Dassault Systèmes will bring similar opportunities to businesses and R&D labs at the AMRC. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Humber Manufacturer Acquires New Warehouse

Humber-based manufacturer has acquired a new 42,000 sq ft warehouse in Scunthorpe. For this acquisition Birkdale Manufacturing Group received a £400,000 Growing the Humber Business Investment Grant from North Lincolnshire Council to ensure the expansion could go ahead. The company manufactures garage doors, roller shutters, composite doors, awnings, pergolas and window blinds. “In the last few years Birkdale has invested heavily on new machinery, which allowed us to increase our capacity to cope with extra demand. This created workspace issues so to cope with growth, further investment and larger floor space was required,” said Birkdale owner Simon Sturman. “With the help of North Lincolnshire Council’s business development team, we’ve been able to find premises and secure grant money, which added to our own £1.4 million of investment allowing us to bring forward our expansion plans.” Having worked in partnership with the council to secure funding from the Humber Local Enterprise Partnership, Birkdale has now entered into a lease-purchase agreement to move sites on the Queensway Industrial Estate. Marketed by PPH Commercial for £1.25m, the detached premise has a purpose-built warehouse and distribution facility along with internal office and staff facilities. “Some local authorities can borrow money for as little as 1 per cent, so it makes sense to invest this in commercial property which can offer an annual yield of anything from three to as much as 7 per cent. In my opinion, North Lincolnshire Council should be praised for adopting this brave and innovative approach to their investment strategy. Not only does it offer good returns, but it also brings added security to the local economy,” added Duncan Willey, the divisional director who completed the sale for PPH Commercial. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Farm Invests in Robotic Milking Machine

Farm Invests in Robotic Milking Machine : £350,000 have been invested by a farm in robotic milking machine that allows cows to milk themselves. James and Alec Cowan have signed up with dairy farming co-operative, South Caernarfon Creameries (SCC), and have installed the machine. The robotic milking machine learns the identity and individual characteristics of every cow in the 120-strong herd, at the brothers’ mid Wales farm, Blaencwmpridd, in Llandysul, Ceredigion. The technology is predicted to increase milk production at the JH Cowan & Sons farm to 1.2 million litres a year at, with milking going on 24 hours round the clock and cows being milked up to five times a day. “It is fascinating to watch how it works, the cows wander in and it picks up the teats every time. The robot uses lasers to learn the shape of the individual cows so it knows how to fit best with each one. It is better for the animal welfare, because they are milked when they are ready,” said James Cowan. “It works on all levels. Happier animals provide better food. It will increase milk production too because we are milking when the cow is ready. We produce between 4,000 litres and 8,000 litres a day so overall we will increase production to 1.2 million litres a year. It’s amazing to think that when my father came to Wales in 1948 as part of the war effort he was 14 and they were milking cows by hand, now I am milking cows with robots,” he added. South Caernarfon Creameries has 130 farming members across North and Mid-Wales and processes more than 100m litres of Welsh milk each year to make a wide range of cheeses for the retail and wholesale market. “We are delighted to welcome James and Alec as members at South Caernarfon Creameries. Our farming members are at the heart of everything we do to create high quality cheese here in Wales and it is fantastic for us to be able to work together with them to help secure the future of dairy in Wales,” commented Alan Wyn Jones, managing director at South Caernarfon Creameries. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Brexit Uncertainty Is Affecting the Manufacturing Sector

A new survey is showing that South East manufacturers are experiencing far more difficult trading conditions as they enter the autumn due to the Brexit uncertainty dragging on. According to the Q3 Manufacturing Outlook survey published by trade organisation Make UK and business advisory firm BDO, while both output and total orders have remained positive they fell dramatically compared to the second quarter. Output reduced from +42 per cent to +6 per cent in the last quarter while the order balance, despite being positive, has also reduced significantly. This fits with the national picture of output continuing to decline from the first half of the year which was boosted by artificial stockpiling reaching record levels. Export orders also fell in the South East despite a cheaper pound as overseas customers move away from British goods and the global slowdown and trade wars take effect. The more difficult picture is reflected in a number of other indicators. Intentions to recruit and invest have both turned negative showing that the region can not escape the Brexit and trade uncertainty which is hurting other regions. As a result of this mixed picture, Make UK is now forecasting manufacturing growth of just 0.1 per cent in 2019 and a 0.6 per cent in 2020. GDP is forecast at 1.2 per cent in 2019 and 1.6 per cent in 2020. GDP is forecast to be 1.1 per cent in 2019 and 1.4 per cent in 2020. “Industry is facing a perfect storm of factors, compounded by a hard Brexit which could not be coming at a worse possible time,” said Make UK region director for the South East Jim Davison. “In normal circumstances a global slowdown on its own would be enough, but add trade wars and the biggest shock to our economy since the war and there seems little doubt that, barring a remarkable turnaround, the sector is heading for recession.” “Global competition, skills shortages, lack of a coherent industrial strategy from government and continuing technological disruption has made UK manufacturing a challenging sector for decades,” Mark Hutton, head of manufacturing at BDO in Gatwick and Guildford, added. “The long shadow cast by the possibilities of a no deal Brexit and the uncertainty of recent months has only added to the difficulties for manufacturers in the South East. “A cliff-edge decision on a deal or no-deal Brexit will mean a double whammy of continuing weaker demand for products and fundamental disruption to supply chains. The government must strain every sinew to reach a Brexit deal that protects UK manufacturing.”

3 Ways Manufacturing Businesses Can Prepare for Brexit

On 31 October 2019, the UK will leave the European Union (EU). UK manufacturers should and will have been preparing for that date, whether a final Brexit deal is made or not. UK manufacturing is resilient and has a rich history, accounting for nearly half of UK trade. But how will Brexit affect manufacturing? This article will explore that issue and offers three pieces of advice to keep manufacturing businesses moving. How will Brexit affect manufacturing? Brexit will represent opportunities as well as threats, and manufacturing business leaders need to prepare, whatever happens, and irrespective of whether tariffs and non-tariff barriers are put in place. Worldwide, there will be new market opportunities and supply networks to tap into, with room to forge new relationships. In January 2018, the UK government released a white paper with a post-Brexit modern industrial strategy, promising billions of pounds of investment in technology and Industry 4.0, as well as a commitment to play a more active role in boosting the industrial sector. Smart and transformational technology, such as the Internet of Things, may allow businesses to take advantage of what could be on offer. One of the main issues of Brexit for manufacturing companies (and businesses on the whole) is the lack of information on what precisely will happen. Normally when businesses plan, they’re basing plans on hard facts and information. Brexit is different – businesses need to plan with unknowns in mind, even taking speculation and hypothetical scenarios into account. Whatever the future scenario, UK manufacturers and distributors need to make sure they’re prepared with the right tools and insights to make the most of a new era. The most successful companies will have visionary leadership and will play to their strengths while minimising their weaknesses. Three ways to prepare for Brexit Here are three areas that manufacturers need to consider in light of Brexit. 1. Keep goods moving Perhaps the most immediate priority for British manufacturers (and distributors) is to understand how various Brexit scenarios may affect their supply chains and the movement of goods. Considerations include: Tariff exposure and other costs. Compliance – irrespective of a Brexit deal (and free trade agreement between the UK and EU) or no-deal (and the transition to World Trade Organisation rules) goods will need to be declared, with custom procedures applied and opportunities for tax/duty planning. Relationships with suppliers – if manufacturers rely on certain components, understanding how this will work after Brexit will be a priority as lead times may increase. The security of customer relationships and the effect on demand volume, contract terms, pricing and rebates. The potential loss of EU research and development grants, and the impact on product marketing and procurement. UK manufacturers should examine their supply chains closely, taking care to understand where delays may potentially hit the business. They should also make good use of data analytics – this could help them examine how they can consolidate goods and understand if warehouses need relocation. Manufacturers should also be asking their suppliers about their own plans for Brexit. One option for UK manufacturers is to become an Authorised Economic Operator (AEO), which is an accreditation that allows businesses to register to apply simplified customs procedures to fast-track their goods through customers border controls and provides assurance to HMRC that their import/export practice is secure. Supply chain strategies needn’t just be about mitigation. What forward-thinking manufacturers should be looking at is challenging what’s happening in their supply chains and doing things differently. Reducing lead times and deferring the time when any duties need to be paid makes sense in almost every scenario. British manufacturers may benefit from considering trade opportunities with countries outside of the EU, such as China and the US. This will have its own set of challenges when it comes to culture and language. 2. Adopt new technology and innovation The fourth industrial revolution, or Industry 4.0, is already making a considerable impact on British manufacturing. Bringing together technology such as the Internet of Things (IoT), cloud computing and artificial intelligence (AI), UK manufacturers should embrace technology in a post-Brexit world. It offers great opportunities and benefits when it comes to productivity and efficiency. AI and automation for example, provide an opportunity for businesses to scale up volume to meet demand from outside of the EU, helping to keep production costs low and assisting the development of new products for new markets. Automation has already changed manufacturing processes around the world and there will be new systems that can perform tasks normally done by humans, which will save money and improve efficiency. Rather than purchase technology in a haphazard way, it’s vital that UK manufacturers understand the specific business challenges they have and make the right investment, efficiently and effectively, to gain a competitive edge. This is particularly important for large manufacturers, which through research, development and investment could already be familiar with what technology can do for them. They won’t be simply thinking about the latest shiny new tech but rather choosing digital technology that can transform their business processes and which has been validated by similar companies. Ultimately, preparing for Brexit through digital transformation and technology investment is very similar to preparing for any other type of business challenge – finding ways to satisfy customers, create better quality products at lower costs, and making them available to as many people as possible in the global marketplace. 3. Invest in the right people Managing Brexit is also about recruiting and retaining the right staff to drive success. To fully implement the benefits of Industry 4.0, UK manufacturers must have a strategy of upskilling existing employees to deliver digital transformation. Manufacturing is changing. Take 3D printing for instance – additive production techniques have radically transformed production processes. This moves away from traditional subtractive production and the traditional assembly line, and towards a process where skilled engineers design manufacturing products digitally. Of course, the possible restriction of free movement across the EU may cause businesses to face problems of recruiting enough people to run traditional

Industry 4.0: Why you need to invest in it to increase growth

Industry 4.0: Why you need to invest in it to increase growth : Manufacturers in the UK finished the year positively, with the strongest three months for growth since 2014. Markit/Cips UK Manufacturing Purchasing Managers’ Index figures showed that activity and new orders expanded throughout the past 17 months in the UK, with firms increasing production in response to new orders and the launch of new product lines. However, this is not the time for your manufacturing business to rest on its laurels. Investment in capacity and machinery is needed to take advantage of expected growth, with many leading manufacturers fast becoming “Industry 4.0” ready. What is Industry 4.0 and why does it matter to you? Industrial revolutions are huge, significant events and observers believe we’ve had four of them. The first was initiated by the introduction of the commercial steam engine and the birth of the textile industry. The second was sparked by electricity and mass production. And the third was triggered by the computer after World War 2. Professor Klaus Schwab, founder and executive chairman of the World Economic Forum, believes we’re well under way with the fourth industrial revolution. Also known as Industry 4.0, it refers to major innovations in technology that are coming into maturity at the same time, embedded by companies around the world, integrating the virtual and physical worlds to bring forth powerful new ways of working. Examples of this technology include: Internet of Things The fusion of physical objects such as software, sensors and electronic items with internet and machine-enabled data collection and transfer. IoT allows real-time communication, initiating physical systems and giving rise to smart cities. It offers you the opportunity to build digitised and connected supply chains – completely integrated ecosystems that are fully transparent to the contributing marketing, product development, manufacturing, and distribution departments. Big data and advanced analytics With the Internet of Things comes a huge amount of data – and the way your business reads and analyses that information is important. In manufacturing, the availability of data from product development, production and testing can add new dimensions to the way you manufacture goods, offering better innovation, marketing and decision making. Robotics and automation Robots are already used extensively in the manufacturing world – mechanical arms on assembly arms for example. Industry 4.0 could see the contribution of robots massively increasing, and consider the possibility of building “smart factories” where robots take ownership of manufacturing and bring goods to customers with limited human input, due to computing and communication systems linked with physical systems. Simulations, 3D printing and augmented reality Already commonplace today, goods can be virtually modelled and tested, saving time and reducing the materials, efforts and money spent. Through 3D printing, we can see the creation of customised, complex and lightweight designs at remarkable speeds, while augmented reality sees a future where employees can be trained on the job far more effectively than with paper or monitors. Why you should be investing in industry 4.0? Industry 4.0 isn’t a buzzword. In fact, businesses are already putting down investment – and organisations that aren’t are at risk of being left behind. PwC claims Industry 4.0 will revolutionise industrial production, with businesses generating on average 3.6% per annum cost reductions until 2021, driven by internal improvements and working more closely across value chains. They also expect to generate 2.9% p.a. in increased revenues by digitising products and services, as well as developing new digital service offerings. Meanwhile, 33% of industrial companies say they’ve already achieved advanced levels of digitisation, and 72% of companies expect to achieve advanced levels of digitisation by 2020. Increased competition is leading a focus on servicing customers, which requires your manufacturing business to explore new ways to deliver products and services – the change in processes and business models that Industry 4.0 is all about. Nick Castellina, research group director at Aberdeen, says: “Products may need to be more customisable, requiring a change in the ways production and delivery are handled. Many of these changes would be impossible in existing business systems. Therefore, manufacturers have prioritised modernising business systems as their second goal for the near future.” Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Sales at Manchester Based Food Group Are Soaring

Sales have soared at the Manchester-based food business behind the Paul Hollywood, St Pierre and Baker Street brands with the company – which secured a multimillion-pound investment during the year – eyeing further growth. St Pierre Groupe recently rebranded from Carrs Foods. It was established in 1986 as part of a large European bakery group. For the year to 31 December 2018, the company reported turnover of £69.5 million compared to £49.4 million the prior period. Moreover, pre-tax profits also increased from £5.2 million to £6.9 million. Branded products make up most of the business, with the St Pierre line sold in the UK, Ireland and throughout the US, with the latter being its strongest market for growth. Baker Street is sold primarily to the convenience and cash and carry sectors. It expanded during the year with a new wellness offer – which includes breads made with rye, nuts and seeds in a bid to fill a gap in the UK market for longer life products with healthier attributes. The Paul Hollywood Ready to Bake line is to grow in the comping year, with new products lined up for new categories. “Everyone at the St Pierre Groupe has worked very hard to build us into a fast-growing global bakery business and we are truly proud of our achievements. It’s been an incredibly exciting year for the business. We’ve not only posted very strong financial results, but we were also recognised with a Queen’s Award for Enterprise in International Trade – having become one of the ten biggest bakery brands in the US,” said Jeremy Gilboy, founder of St Pierre Groupe. “We’re planning on more of the same great progress in the next year as we concentrate efforts on increasing distribution in the UK, growing internationally and continuing to invest in our brand and marketing to keep on growing sales.,” he added. Earlier this year, the group secured a £6.7 million investment from BGF and partner Lloyds Bank, facilitated by Grant Thornton. The funds were earmarked for accelerating international growth. Elsewhere, former Tyrrell chief executive David Milner joined as non-executive chairman. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News