Automotive Manufacturers Are in a Cutting-Edge Technology War

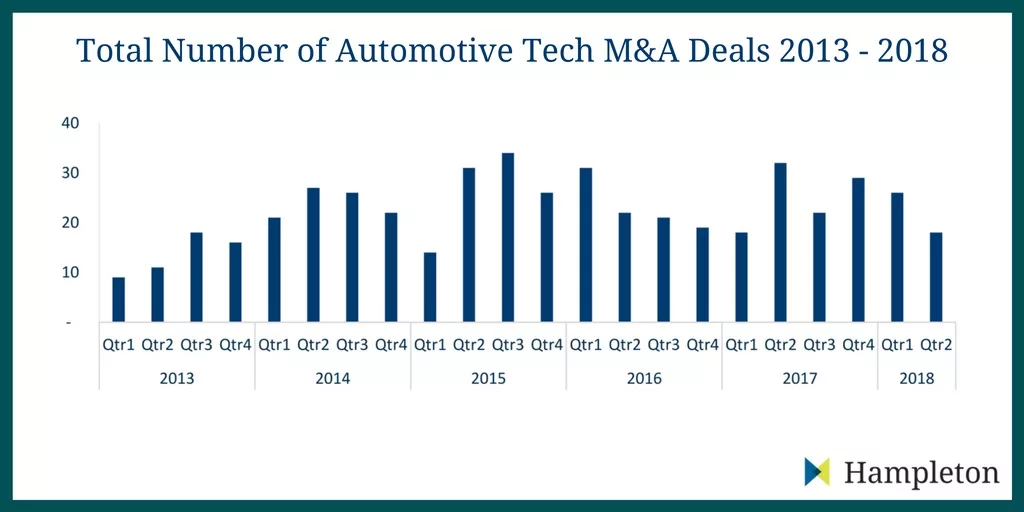

Automotive Manufacturers Are in a Cutting-Edge Technology War : Hampleton Partners, the international technology mergers and acquisitions advisors, have unveiled the latest Automotive M&A Market Report that outlines how the world’s automotive manufacturers are competing fiercely with suppliers as well as newer market entrants, such as Waymo and Tesla, to acquire the cutting-edge auto businesses and technologies that are transforming the future of personal mobility and commercial transport. “The autotech sector is proving an attractive investment for manufacturers who need to transform their business models to become mobility providers and for Silicon Valley startups and tech giants who are attempting to stake an early claim for market share on the roads, in a market poised for a minimum decade of growth before it hits maturity. This race for the best technology and the best teams can only boost autotech valuations even more,” commented Jo Goodson, managing director, Hampleton Partners. Hampleton estimates that the market is on track to deliver around 100 transactions in 2018, reflecting the fast-moving changes in driver behaviour and their quick acceptance of tech innovations such as parking payment; ridesharing; carpooling and car purchasing apps and portals. Moreover, the report also revealed that deal values were up by 54% in the first half of 2018 vs. teh same period in 2017, reaching $2.9 billion. The number of private equity transactions in the autotech sector totalled ten announced deals this year, up from just a handful from the full year in 2017. This increase in investment flowed into early stage companies as well as more established business models. In an age of cyber hacks and vulnerabilities, with connected cars becoming a reality, companies are looking to acquire or invest in solutions that improve trust and reliability. Any technology that has the potential to improve safety on the roads in an era of autonomous vehicles is a financial target. “Consumers and commercial fleet managers are embracing new technologies that are being launched to help them manage their mobility in the most cost-efficient way, maximise their safety on the road and reduce their impact on the environment,” concluded Jo. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

John Moylan Says UK Must Brace Itself For Brexit Woes Despite Toyota Making Britain Part Of Its Long-Term Future

John Moylan, the BBC’s car manufacturing correspondent, says the UK must brace itself for Brexit woes despite Toyota making Britain part of its long-term future. The BBC’s car manufacturing correspondent John Moylan says, despite Toyota announcing plans to upgrade its UK plant with its New Global Architecture, its new system for producing vehicles worldwide, UK car manufacturing must brace itself for Brexit woes. Moylan said that Toyota’s decision suggested the company saw the UK as playing a major part in its global activities but “the UK’s automotive industry knows that Brexit is coming and with it the possibility of tariffs and complex customs arrangements. That threatens the competitiveness of carmakers that rely upon the kind of just-in-time manufacturing which Toyota pioneered.” Moylan’s comments come after Toyota announced that its Burnaston plant in Derbyshire will be boosted by a £240m investment as the production facility is upgraded to its new global platform. Toyota, like other carmakers, have previously enjoyed tariff-free access to the EU and will hope to continue to do so following Britain’s split. This has been important for the Burnaston facility as more than 85% of its output is shipped to mainland Europe. The news of major investment comes as a massive relief to the thousands of workers employed at the facility. But it also suggests optimism post-Brexit. Dr Johan van Zyl, the president and Chief executive of Toyota Europe, said: “We are very focused on securing the global competitiveness of our European plants. This upgrade is a sign of confidence in our employees and suppliers and their focus on superior quality and greater efficiency.” He welcomed a £21m contribution from the UK Government as part of the investment. This “Demonstrates that, as a company, we are doing all we can to raise the competitiveness of our Burnaston plant in Derbyshire. Continued tariff-and-barrier free market access between the UK and Europe that is predictable and uncomplicated will be vital for future success.” “In essence, the £240 million will be spent on upgrading Burnaston’s equipment and systems – rather than adding to the firm’s 3,100-strong workforce,” said the Derby Telegraph’s Robin Johnson. “Toyota is looking to standardise many of the components and processes it uses across its factories – which collectively will help it to produce “This kind of forward-thinking will hopefully off-set any nasty shocks the company may encounter if the UK is unsuccessful in its export tariff negotiations with the EU. It is clear that the top brass at Toyota think very highly of the Burnaston factory and its UK workforce. Back in 2015, they decided to entrust the factory with the production of an updated version of the popular Auris hatchback and the all-new Avensis. Of course, this was all before there was any talk of Brexit.” Business Secretary Greg Clark said Toyota’s investment “underlines the company’s faith in its employees and will help ensure the plant is well positioned for future Toyota models to be made in the UK”. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Lexus Announces Pricing for All-New 2018 LC Performance Coupe

Since the premiere of the Lexus LC 500 performance coupe last year, the most frequently asked question has been, How much will it cost? Today that question was answered with news that both the 2018 LC 500 and its hybrid sibling, the LC 500h, will have Manufacturerâs Suggested Retail Prices (MSRP) below $100,000 when they arrive at dealerships this May. The all-new LC 500, powered by a normally aspirated 5.0-liter V8, matched with the first direct shift 10-speed automatic transmission to be featured in a luxury car, delivering 471 horsepower and 398 lb.-ft of torque, will have a starting MSRP of $92,000. The LC 500h, powered by 3.5-liter, V6 full hybrid powertrain, delivering a total system output of 354 horsepower, will have a starting MSRP of $96,510. The LC is a new flagship 2+2 performance coupe with avant-garde styling achieved through an unprecedented level of cooperation between design and engineering teams. It is the first model on the new Lexus âGlobal Architecture â Luxuryâ platform (GA-L), designed for new generations of front engine/rear-wheel drive Lexus models. As the first model to benefit from Lexusâ new Multi-Stage Hybrid system, the LC 500h delivers efficient environmental performance without sacrificing powerful driving performance. The LC will be equipped with an array of standard features such as ultra-compact triple projector LED headlamps, arrowhead daytime running lights (DRL) combined with the triple-projector headlamps to create the next-generation Lexus lamp signature, three-dimensional rear lamp, Drive Mode Select, paddle shifters, next-generation Remote Touch Interface with touchpad, Lexus Premium Audio, and a color 10.3 inch TFT multi-information display. All LCs are equipped as standard with Lexus Safety System+, a package of active safety features including Pre-Collision System with Pedestrian Detection, All-Speed Dynamic Radar Cruise Control, Lane Keep Assist/Lane Departure Alert with Steering Assist and Intelligent High Beam. Optional equipment on the base LC 500 and LC 500h models includes 20 and 21 forged wheels, Mark Levinson audio system, Limited Slip Differential (LSD), Blind Spot Monitor (BSM), Intuitive Park Assist (IPA), Heads-Up Display (HUD) and Cold Area Package, which includes heated steering wheel and windshield de-icer. Article taken from Automotive World.

Rolls-Royce Names Partners for UK SMR

Rolls-Royce has named the companies it is working with to bring a small modular reactor (SMR) to market in the UK. Amec Foster Wheeler, Nuvia and Arup, together with the Nuclear Advanced Manufacturing Research Centre, are working with Rolls-Royce to develop the latest technology reactors, a spokesman for the British engineering firm told World Nuclear News today. “Other names will emerge in due course,” he added. In October last year, Rolls-Royce said a UK SMR could provide a £100 billion ($127 billion) boost to the UK economy between 2030 and 2050 because the companies involved are either UK-owned or have a strong UK presence. The latest announcement comes as British ministers are looking to support the development of SMRs and civil nuclear innovation, with up to £250 million in funding, and also to publish a green paper on Industrial Strategy later this month. The spokesman said Rolls-Royce is teaming up with a “raft of British engineering giants” in a bid to make SMRs a reality in the UK, creating up to 40,000 high-value British jobs and intellectual property, and opening up a £400 billion export market. “We are working with some of Britain’s most experienced civil engineering companies and nuclear research organisations to realise the huge potential of small modular reactors for the wider UK economy. We share a common belief that a home-grown SMR program can play a key role in strengthening the UK’s energy mix and security, while creating valuable intellectual property, exports and jobs. We are working together to deliver a whole power plant which could be up and running in just over a decade and provide a boost for the UK’s industrial strategy.” The companies are looking to create a partnership which will build entire running power plants “capable of powering a city the size of Leeds” – which has a population of about 750,000 people. Once the initial design is licensed, parts can be made on a factory production line relatively cheaply, the spokesman said. Interested in this article? Read more at World Nuclear News.

Toyota to Increase R&D Facilities in China

Toyota has announced that it is to expand its facilities in China. Toyota Motor Engineering & Manufacturing (China) Co Ltd (more commonly referred to as TMEC) is based in the city of Changshu in Jiangsu province. The plan includes improvements to the existing laboratory facility, the construction of a new laboratory, the creation of a battery evaluation and test facility, and improvements to test tracks on the premises. These are scheduled to be completed from late 2018 onwards. Hiroji Onishi, Toyotaâs CEO for the China Region, said at a press conference: Efforts are being directed toward the re-inforcement of local R&D capability for the long term. We hope to train as many local engineers as possible and to develop more cars that would satisfy the needs of our customers in China. He added that preparations are underway for Toyota to begin demonstration tests for fuel-cell vehicles in China. Article taken from http://www.machinery-market.co.uk/news/16004/Toyota-to-increase-RandD-facilities-in-China Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News Manufacturing & Engineering Magazine (MEM), is a the leading UK based monthly print & digital publication focused on promoting innovation in manufacturing and engineering available here in the UK. We cover : SUSTAINABILITY (Waste & Water Management, Recycling, Energy); INMOTION (Rail, Marine, Aerospace, Automotive, Defence); INFRASTRUCTURE (Oil & Gas, Nuclear, Construction); Healthcare (Medical), TECHNOLOGY(Printed, Connected, Software, Composite); MANUFACTURING (Chemical, Metals, Plastics, Electronics, Electrical); CONSUMER GOODS(Furniture, Electrical, Electronics, Food) to name but a few. We have over 50,000 views of each issue of MEM on average in 2022 and go to print monthly and also publish in our newsletter, (each issue is available free for 12 months digitally). Our focus is aligned across the next 12 months with our global media partnerships around Trade Events and also contains original content.

Alphabet Data Share Deal Gives BMW/Mini Drivers a ‘WOW’ Factor

Alphabet is urging more manufacturers to share vehicle maintenance-related data with leasing companies, following the successful launch of its Tele-services initiative with BMW UK earlier this year. Since January, when Alphabet and its BMW parent began trialling data sharing, the leasing company has received more than 13,200 service maintenance repair (SMR) data alerts for its BMW- and Mini-maintained vehicles, enabling it to take a proactive approach, and use preferred repairers. Data is provided by the manufacturer which enables us to capture the servicing that is required on those vehicles, to liaise with the customer and steer the customer down the channel that we see fit, be that to the BMW or Mini network for repair, be that to an independent network or be that to a fast fit, said Kit Wisdom, head of technical services at Alphabet, who was speaking at the International Auto Finance Network (IAFN) conference. Wisdom said that in some cases Alphabet is aware of a maintenance issue, such as engine oil being due for replacement, before the company car driver sees a message in their vehicle. Alphabet is also aware when the next service is due and when brakes are expected to be required based on usage of that vehicle, meaning it can contact the driver or fleet manager to get the vehicle booked in. Customer feedback is very positive, Wisdom said. For us to say âwe know your brake fluid needs to be changedâ or âwe know that your brake pads in the front need to be changed, we can book that in for you next weekâ, itâs a âwowâ moment for the customer. It has been really powerful. For fleet managers this proactive approach can help avoid neglected service warning lights or unexpected maintenance issues and help reduce downtime. The latest phase of Teleservices has seen Alphabet representatives gain access to BMW service centresâ online service booking systems so they can view real-time workshop availability and book a service slot while the customer is on the phone. Read more at http://www.fleetnews.co.uk/fleet-leasing/news/latest-fleet-leasing/2016/11/30/alphanet-data-share-deal-gives-bmw/mini-drivers-a-wow-factor

Formaplex Expands Manufacturing Capabilities with 120,000 Sq Ft Facility

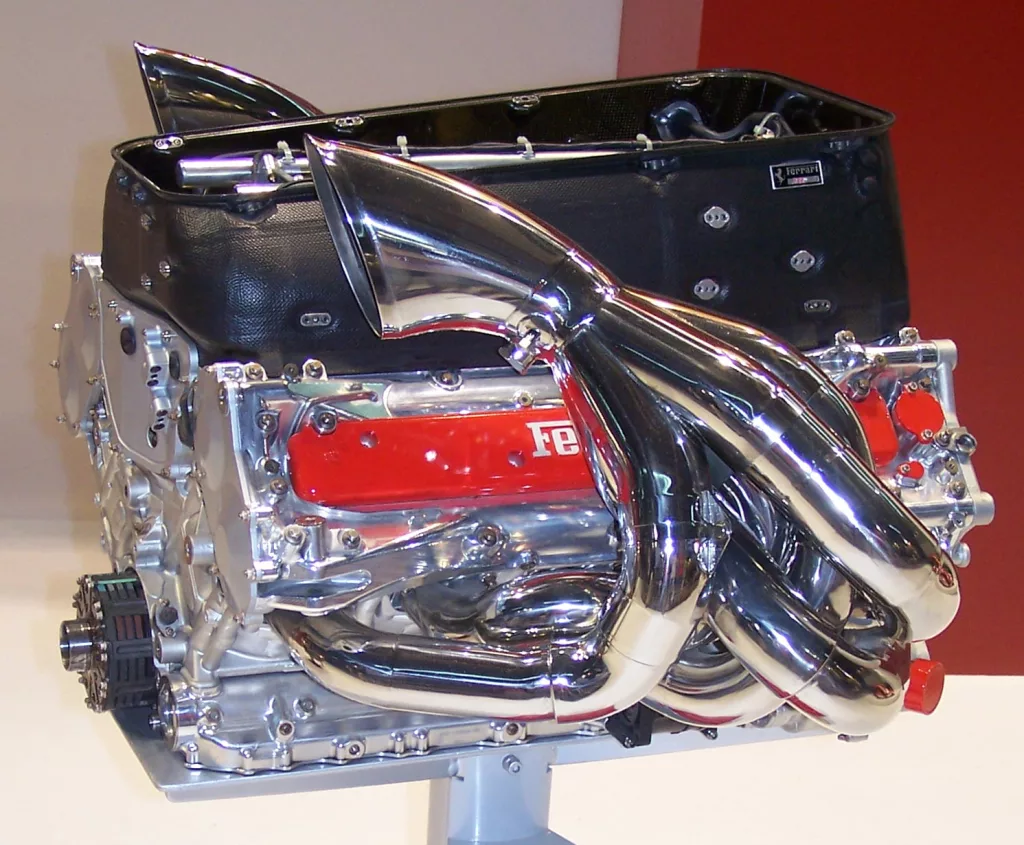

Hampshire-based engineering firm, Formaplex, which supplies tooling and lightweight components to the premium automotive, F1 and motorsport industries, has expanded with the opening of a new 120,000 sq ft facility. The company, which has been shortlisted in the Large Manufacturing Company of the Year category at the upcoming Insider Made in the South East Awards, said Voyager Park will increase production space by 80% to support the businessâ future growth. Altogether, the firmâs total footprint now spans 270,000 sq ft across four sites in Horndean, Portsmouth, Cosham and Havant. The new site will accommodate a total of 15 injection mould presses to support the rising demands of lightweight moulded components, along with in-house finishing, assembly and metrology departments. It has created around 100 new job opportunities. Mike Bryant, Formaplex Chief Executive, commented: “We have experienced steady growth over the last five years, resulting in our current sites working at full capacity. This growth has been positively impacted by confidence in the automotive sector and increased international demand for UK premium car brands. “We are currently producing 600 injection mould tools and moulding approximately three million thermoplastic components per year, predominantly for the automotive industry. Our new premises will ensure we have the additional capacity to continue to provide our services and world class products to our blue-chip customer base.” Formaplex was established in July 2001 and was acquired in a management buyout supported by private equity company DunedIn in 2007. Earlier in the year, Formaplex unveiled a new 11,000 sq metre factory on its Cosham site, near Portsmouth. The new technical centre âVoyager Parkâ is set to increase production space by 80% to support future growth of the business. The new £6 million facility will accommodate a total of 15 injection moulding machines, for producing lightweight-moulded components, together with in-house finishing, assembly and metrology departments. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Are Mazda’s designs the best around?

Are Mazda’s designs the best around? : It’s hard to think of a car maker with a better-looking range of cars than Mazda. From the smallest 2 to the largest CX-9. Mazda speaks about a ‘design language’ more than most manufacturers, stuff that typically can be jargon and not prevent a car from looking like a dog’s dinner despite all those lovely PowerPoint slides of some waterfalls and a spiralised cucumber. But whatever the language behind the ‘Kodo – Soul of Motion’ design philosophy that Mazda employs, I’ll happily speak with it. Mazda has a habit of lurching around between generations of car trying to reinvent itself. Such an approach can reveal an overall lack of confidence and direction in what is going on. You don’t have to look too far up the road towards some of Mazda’s Japanese counterparts for current evidence. But back in 2011, Mazda relaunched itself with a suite of technologies called SkyActiv and the Kodo design language to style its next generation of models. And they all looked lovely, looking as good as they drove for once. Now a potential crossroads has arrived. For at the LA motor show, we have the first Mazda to be replaced since it went Kodo and SkyActiv: the second-generation CX-5. Thankfully, the new car is a subtle evolution of the existing theme rather than the complete rethink we’ve tended to see from Mazda over the years. They must know they’re on to something with this Kodo… So much so that Mazda now wants its models to be seen as “art”, according to design chief Ikuo Maeda. It’s quite a claim and, even as someone who has seen the Mona Lisa on the canvas, I’m not confident of knowing art when I see it or whether or not a car qualifies. To hell with it, though: the new CX-5 is another Mazda that looks great and is a step up again from its already handsome predecessor. If Mazda can keep this up over the next few years as it replaces the rest of its range, they may have to clear a corner of The Louvre for the next MX-5for it’ll be such a stunner. Leonardo da Vinci would approve. Probably. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Manufacturing Underway for The Chevrolet Bolt

The excitement for the launch of the Chevrolet Bolt EV has significantly been heightened as General Motors have confirmed that work is underway at a manufacturing plant in Michigan, following the announcement last week claiming that the company has redoubled its efforts into delivering the hugely anticipated vehicles by the end of this year. âAll Electric. All Efficient. All Aboard.â This is the tag line for the all-electric vehicle that is promising an estimated 238 miles of range per full charge, which will make this the first electric vehicle with over 200 miles of driving range, and with the relatively affordable starting price of under $38,000 The Bolt could eventually prove to be a huge hit in the automotive industry. Models such as the BMW i3 and the Tesla Model S are already out there, but they certainly arenât placed at a price that the majority of people could afford to purchase. Most importantly for Chevrolet, The Bolt is well on track to beat its major rival in the Tesla Model 3 in terms of its release date, with the Model 3 only expected to enter production midway through 2017. However, the bad news is that The Bolt is not expected to get anywhere near the Model 3 in terms of initial sales, with early predictions suggesting there will be fewer than 30,000 Bolts moved in its first year, which is nothing on the mammoth amount of pre-orders for the Model 3 which amounts to over 400,000. So could this news be the kick start that was needed for the electric car industry? It seems like this could be the first signs of affordable electric vehicles in the US, and people will now be able to get the first taste of The Bolt at the end of 2016 should everything go to plan. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Featuring Torotrak: Interview with Tobias Knichel, Business Development Director

Torotrak – Accelerating in Force (The Following is a Promoted Article) One of the biggest challenges facing the modern automotive industry is negotiating the various changes in carbon emissions legislation whilst still accommodating the performance needs of the consumer and, critically, at a low cost, insists Tobias Knichel, Business Development Director at Torotrak. Confronting that issue head-on, Torotrak has developed a range of efficiency-enhancing solutions and promises to deliver a cleaner, greener and more efficient future and at rate which is affordable so as to be viable sector-wide. Founded at the turn of the millennium, one of Torotrakâs sites sits in the heart of Motorsport Valley in MEPCâs Silverstone Park and is very much dedicated to improving vehicle performance with the environment firmly in mind. Applying its passion for quality engineering to develop pioneering products and provide expert engineering in the automotive industry, the company provides a number of advanced mechanical technologies for use in commercial, on and off-road vehicles as well as passenger car industries. So often, the case of increasing a vehicle’s efficiency and reducing its carbon emissions comes at the cost of vehicle performance and responsiveness, as well as representing major costs businesses simply cannot support. With three core products, Torotrak focuses on key areas of supercharging, kinetic energy recovery and main drive transmissions, promising optimised efficiency without compromising on the operational integrity of a vehicle. The superior performance of its V-Charge supercharger, for instance, provides exactly the amount of air that the engine requires at every operating condition, delivering from 0 to 95 per cent of target torque in just 400 milliseconds. With near silent operation, the V-Charge is testament to Torotrak’s mechanical engineering excellence, a knowledge core allowing the company greater flexibility in design and providing its customers with a viable means with which to reduce their environmental impact. As Knichel corroborates: In several markets, we compete against electrical alternatives. Whilst they’re very capable systems and you can achieve good fuel consumption improvements with an electric hybrid vehicle, the costs are prohibitive and that, in turn, restricts them to high-end, luxury vehicles. The USP of our products is that we can achieve very comparable fuel economy improvements but at a much lower cost because our technologies are based on mechanical principles. We can therefore roll them out across vehicle ranges, be that commercial bus or road car, and reap a greater overall reduction in carbon emissions. Following the acquisition of Flybrid Automotive little over two years ago, Torotrak is now able to support the application of its award-winning, flywheel hybrid system (or KERS). A new breed of pragmatic hybrid, KERS technology recovers energy that is ordinarily dissipated as heat during braking events in a smarter and more environmentally-sound way. Mechanical and compact, the pioneering energy-recovery system not only achieves greater efficiency and enhances engine performance but is, too, significantly cheaper in both the long and short term. With each product manufactured, assembled and developed in-house, Torotrak effectively spreads its engineering knowledge across market segments, utilising the same design rules, manufacturing techniques and development processes across the breadth of vehicles in the sector. Promoting cross-pollination between industries and cutting down the costs and lead times associated with outsourcing, the company is able to develop and deliver advanced technology at pace unrivalled by any other. It’s with the combination of engineering esteem and a rapid production process that Torotrak continues to attract international players in the automotive industry; Jaguar being a public example. Working on a 1.8 tonne, diesel Jaguar XF, we were tasked to deliver the superior performance appropriate to such a high-end product, details Knichel. With the installation of a powerful, 60kW kinetic energy recovery system (KERS), we were able to achieve the performance of the V8 petrol equivalent, whilst realising the fuel economy of the four cylinder diesel variant. The expertise Torotrak has built up over the years developing state-of-the-art products extends across design, modelling, product development and prototype build-and-test. Within its specialist facilities and test operations centre, the company offers engineering consultancy services in which to evaluate the specific advantages its products can bring to potential clients. Promoting absolute transparency, Torotrak supports customers to make an informed decision on how to improve vehicle performance, from providing an initial outline of specification, to conducting demonstrations, right through to completing a productionisation process. The process presents the opportunity in which to test the predicted performance and adapt technologies, as well as carry out functional safety analysis and extended durability testing. With the support of the Advanced Propulsions Centre (APC) and Innovate UK, Torotrak continues to develop new products and systems in line with changes in regulatory standard and customer preference. The former, in particular, has been invaluable in facilitating collaboration between SMEs, like Torotrak, and OMEs and larger Tier 1 companies in order to push industry progress, as well as increase the speed at which products are developed and released to the market. A number of projects are already underway at its Leyland site, home to its production and long-term development facilities, and Torotrak is very much committed to driving evolution in the automotive sector as a whole. By working together with our customers and suppliers, we’re always finding new arenas and applications for our products, asserts Knichel. Our core ambition remains to make performance-enhancing technologies accessible to the whole of society and, in doing so, stimulate a shift toward a more environmentally-sustainable automotive sector. We will therefore continue to work in a very diverse environment, developing solutions for some of the largest car manufacturers as well as small businesses in the bus and commercial vehicle sector.