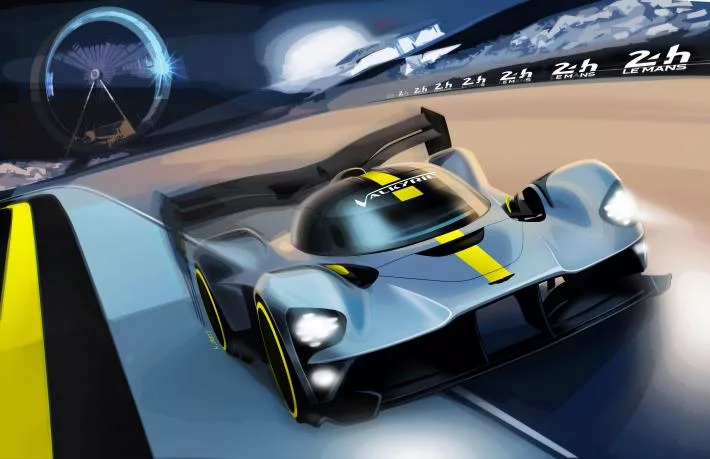

Aston Martin to Race a Valkyrie Hypercar in 2021

Less than two hours after the new regulations had been officially made known, Aston Martin announced that the British marque will enter at least two works Valkyrie hypercars, 60 years after its only outright win at the 24 Hours of Le Mans. The Valkyrie will race the 2020-21 World Endurance Championship, which ends with the 2021 24 Hours of Le Mans. The racing version of the Aston Martin Valkyrie has what it takes to make a bid for victory. The hypercar will be fitted with a specially-designed 6.5-litre V12 engine. “The FIA World Endurance Championship and the 24 Hours of Le Mans represent the ultimate challenge for the Aston Martin Valkyrie – the world’s most extreme hypercar”, said Aston Martin VP and Chief Special Operations Officer David King. “Designed and built with the purpose of pushing boundaries on the road, it’s natural to conclude that the next stage in its development would be to measure its capabilities on the track. I can think of no better way to do that than to compete in a world championship and the most prestigious and famous race of all.” “Le Mans has always been about technological diversity”, he adds. “The ACO is good at offering something for everyone. Balancing performance won’t be easy, but it’s in the right spirit. We’re very pleased to be able to fight for the top honours again. It has always been our dream. The new regulations are a licence to dream.” “David Brown came here in 1959, with a car and a team of drivers capable of winning. We intend to do the same in 2021”, concluded Andy Palmer, Aston Martin Lagonda President and Group CEO. “The Aston Martin Valkyrie is primed for such a challenge and sits perfectly within the ACO’s new ‘hypercar’ rule framework. Bringing to bear all of our previous experience and knowledge of competing at the top levels of motorsport, we embark on this most ambitious project with the necessary ingredients for success. What could be more evocative than the wail of an Aston Martin V12 leading the charge into the night on the Mulsanne straight? ” Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Aston Martin New Manufacturing Facility

The new Aston Martinâs manufacturing facility at St Athan in Wales has seen its first phase approaching completion. The work carried out included the creation of a customer and staff reception areas, administration and management offices, and the employee restaurant. Work on phase one of the development at the former Ministry of Defence site started in late 2016, with phase two commencing in April 2017. When ready, phase two will see the three super hangars redeveloped into a state-of-the-art manufacturing facility with Aston Martinâs SUV due to start production in 2019. The St Athan facility is really starting to take shape. With the completion of this first phase, it is another milestone on our journey in Wales, and an important part of Aston Martinâs Second Century Plan, said Andy Palmer, President and Chief at Aston Martin. Work is also well underway on phase II, the rest of the Aston Martin team and I are excited for when St Athan joins our Gaydon and Newport Pagnell facilities as a centre of hand-crafted manufacturing excellence, he added. Aston Martin chose St Athan in February 2016 out of 20 potential global locations for its third manufacturing facility. The new plant will bring new jobs in South Wales, with 750 new roles expected to be created. The first technicians have already been recruited and are working on the DB11 at the Gaydon Headquarters, training for the roles they will take up at St Athan. Aston Martin Lagonda Limited is a British manufacturer of luxury sports cars and grand tourers. Their sports cars are regarded as a British cultural icon, mainly because the fictional character James Bond used a DB5 model in the 1964 film Goldfinger. It has over 150 car dealerships in over 50 countries on 6 continents making them a global automobile brand. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Specialist Automotive Manufacturers Expected to Increase Volumes if Market Stays Promising

Specialist Automotive Manufacturers Expected to Increase Volumes if Market Stays Promising : A range of UK specialist manufacturing companies such as Aston Martin, Lotus and Rolls-Royce are expected to get a boost to their production. The UK Specialist Car Manufacturing Report 2017 has been published by the Society of Motor Manufacturers and Traders. The report has shown that the UKâs 36 low volume carmakers will produce 60% more vehicles in 2020 in comparison to 2016. This increase in volume is expected if the current economic conditions are to stay the same. Last year, studies have shown that that in the UK, 32,000 specialist vehicles were made. This volume is up a quarter from 2012 and led to a turnover of £3.6 billion. The Report published by the Society of Motor Manufacturers and Traders has also shown that for this period the level of employment is also up in 2016. The UK Specialist Car Manufacturing Report states that 11,250 people were in highly skilled roles in the automotive industry. In addition to this are the thousands of other jobs in the supply chain. The Society has said that is the British economy continues to move in the right direction, in regards to industry standards, regulations and stability after Brexit, then the UK could be able to produce more vehicles in this smaller low volume automotive sector. The Report has shown that the UK could be able to produce over 52,000 specialist vehicles by 2020. This sector is a vital part of the UK economy as it is representative of 65% of the cars that are produced and exported to a range of major market in the EU, USA, Far East and Middle East. On top of this any of the parts that are required to build vehicles in this industry are also made in the UK. Manufacturers in this industry such as Aston Martin, McLaren and TVR have also announced that they will all be building new plants in order to produce new models from 2019 onwards, this will then lead to the creation of specialist jobs and improved marketability. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Aston Martin Plan to offer all Hybrid or Electric cars by mid 2020s

The British Car manufacturers, Aston Martin has announced that all of the vehicles the produce will be either hybrids or completely electric by the mid-2020s. The company is the most recent manufacturer to release the news that they plan to sell cars that have hybrid and fully-electric powertrains by the mid-2020s. The car making company has made plans to be 100% hybrid by the middle of the 2020s, with a quarter of the vehicles they manufacture having fully electric power trains, and no internal combustion engines by 2030. It is great news that manufacturing companies are looking to produce more sustainable vehicles. Aston Martinâs first electrified vehicle will be the RapidE, which is expected to be released in 2019. The new electrified vehicle has been designed from the companyâs four seater saloon vehicle. Also in development is the Valkyrie, a hypercar that will be powered by a V12 hybrid engine. However, the Aston Martin Valkyrie’s electric engine has been added as a boost to performance and the car will not be produced in large numbers. The company maintains their own technological development, creating their own V12 engine. All of the companyâs electric technology for their cars will be manufactured in house. Keeping their technological development in-house allows the company to remain in control of a vital part of their manufacturing operations and will allow them to explore developments that will make all of their vehicles hybrid or electric by the mid-2020s. Volvo has previously announced that they too are aiming to make sure all of their cars feature electrified powertrains from 2019 onwards. It is thought that the Government’s plans to ban all non-electrified vehicles by 2040 has persuaded car manufacturers to begin developing their technology in order to make sure that it conforms to regulation before this deadline.

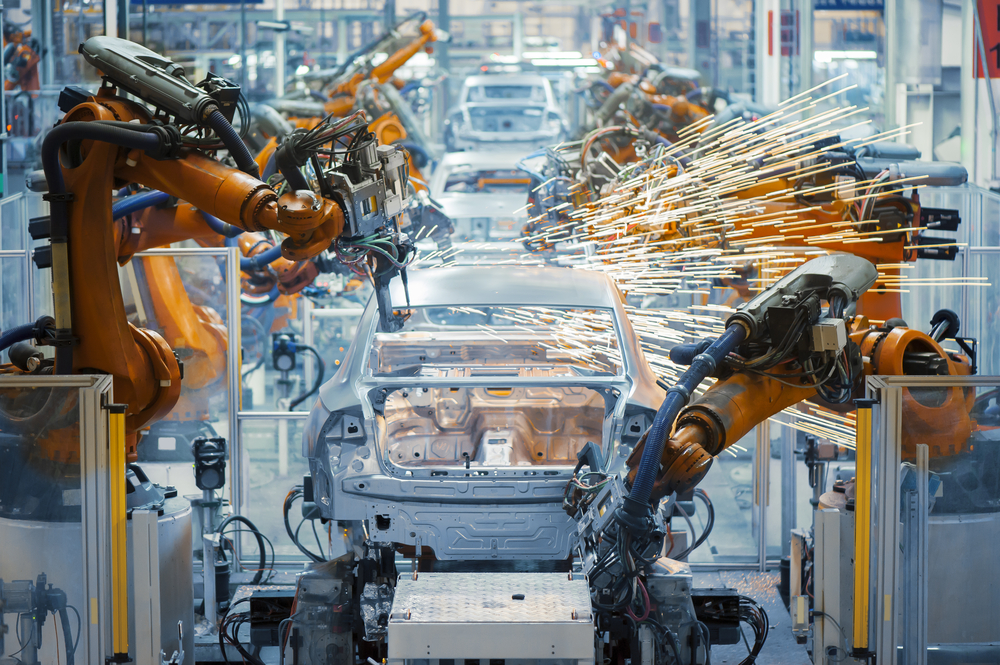

Aston Martin Plans Robotics Switch for Manufacturing

Luxury car maker Aston Martin is reportedly considering a switch to the use of more robots in its manufacturing processes to lower cost and boost profitability. Remarks by CEO Andy Palmer at a Financial Times conference suggest that the company is prepared to make the switch for parts of its production processes such as the assembly line or paint shop. Palmer said Aston Martin “will need further robotisation” to move into the black. The newspaper noted that Aston Martin currently uses a single robot at its Gaydon car factory. The robot is part of the glueing process and is, appropriately, named ‘James Bonder’. However, the FT report says the loss-making company is now planning more investment in production technology in the coming years, including 3D â or additive – printers that can manufacture specialist parts. Palmer also told the FT conference that Aston Martin cars “need to be predominantly built by hand” to maintain the company’s premium appeal, for example in areas such as the hand-stitching of seat materials. Aston Martin recently commenced production of its DB11 model, the first core car launched under an extensive renewal and extension of its product portfolio the luxury carmaker’s six-year ‘Second Century Plan’. After the DB11, which replaces the DB9, Aston Martin is planning to follow with a new Vantage and then new Vanquish. However, the big change to the luxury sportscar company’s business model comes with the new DBX crossover which will be made at a new plant in Wales. CEO Andy Palmer also stresses that Aston Martin is on a journey to becoming an established luxury brand, rather than simply a maker of luxury sportscars.