Following the consolidation of a new acquisition, a global automotive materials specialist claims it can now help automotive OEMs improve the range, power, and reliability of electric vehicle (EV) designs by improving the output of inverters, batteries, and electric motors at a systems-level. The claim is being made by ESI Automotive after the Electrolube brand was acquired by its parent company, Element Solutions.

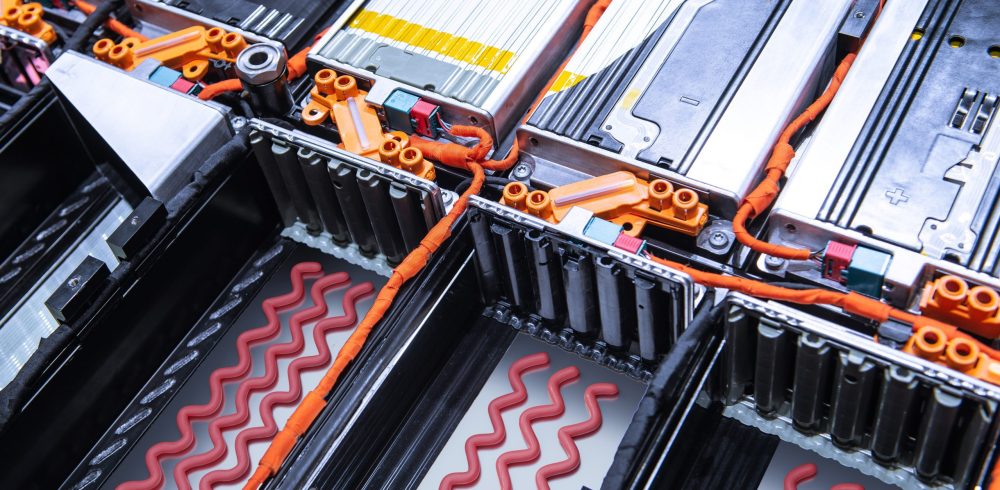

Electrolube is a specialist in thermal gap filler technology, which can be applied to EV battery packs to dissipate heat and improve overall efficiency. Similarly, ESI Automotive has decades of experience working with carmakers in the field of silver sintering to improve the electrical conductivity of inverters, typically by up to 40%. By consolidating the two businesses, Chris Klok, Director of Electric Vehicle Technology, says “ESI Automotive is in a unique position to support OEMs in reaching their EV efficiency goals.”

“While the exact market performance of electric vehicles differs from region to region, there is no doubt that we are seeing a higher volume of sales globally. However, as OEMs transition their production lines to place more of a focus on EVs, there is a need to further increase EV demand and overcome any range anxiety issues that may exist among car buyers,” said Chris Klok, Director of Electric Vehicle Technology.

“As we integrate the Electrolube brand into ESI Automotive, the expertise and knowledge we can pass onto major OEMs and Tier 1 partners is continually expanding. We can now work with OEMs at every stage of the electric powertrain value chain to make significant efficiency gains through the use of new materials and considered materials integration. This enables carmakers to further increase range profiles and bring more efficient and reliable electric vehicles to market.”

A recent project between ESI Automotive and one of the largest global Tier 1 automotive suppliers resulted in an inverter capable of double the previous capacity and with an 80% higher power density. Key to this success was the use of fully sintered silver in place of traditional soldering.

Klok continued: “Silver sintering alone can provide significant efficiency benefits to carmakers and is instrumental in increasing power cycling. When you implement this together with Electrolube’s portfolio of thermal gap filler technology, the improvements in overall EV range and efficiency are significant.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News