The convergence of advanced digital technologies, automation and data-driven insights is bringing to life today, what was once considered the stuff of science fiction. The age of Industry 4.0 and smart manufacturing is giving way to a new level of intelligence, efficiency, quality and safety that is reshaping the very essence of the manufacturing industry.

Over the past few years industry prognosticators have ruminated over exactly what this future of manufacturing work will look like, but in actuality, it’s here today. Take for example a recent Wall Street Journal story that shared what automaker Hyundai is doing in a Georgia, U.S. factory, where some 1450 employees work alongside 750 robots, which handle the repetitive or physically demanding tasks. The article states that the plant is using robotic dogs and humanoid robots – which will soon have arms, legs and fingers, allowing them to sort through and carry parts. By handling more mundane and physically intense activities, humans are freed up to perform more quality control.

The Digital Tools and Technologies of the Smarter Factory

While the robot-filled manufacturing plant is a reality today, there are other technologies that are contributing to the abilities of both robots and humans and making manufacturing increasingly smarter. Consider the following.

Artificial Intelligence. According to the 2025 ETQ Pulse of Quality in Manufacturing survey, an overwhelming 99 percent of manufacturers polled said they are using AI or plan to implement it in the next two years. According to the ETQ survey, the biggest AI use cases are for automating document processing, automating core processes and predicting future trends. But it doesn’t end there. Other applications include quality control via image recognition, supply chain forecasting and anomaly detection in equipment.

The Industrial Internet of Things (IIoT). At the heart of smart manufacturing is the Industrial Internet of Things (IIoT), which connects machines, sensors, devices and humans, collecting and sharing real-time data to better optimize processes and workflow and enable more informed decisions. The ability to monitor operations in real time also enables greater worker safety, as well as more efficient production to meet market demands. Closely aligned with IIoT are digital twins, virtual replicas of a physical product. They allow manufacturers to simulate, test and monitor operations in real-time without disrupting actual processes.

Predictive Analytics. Today’s manufacturing enterprise generates enormous amounts of data on the plant floor, from equipment, production lines and inventory, but also in the business offices from financial data, supply chain partners and customer feedback. Predictive analytics is helping manufacturers leverage all this information to identify trends, anticipate challenges and proactively address them. Quality management systems, driven by predictive analytics, allow manufacturers to optimize production schedules, reduce waste, better forecast demand and even perform root-cause analysis when issues arise.

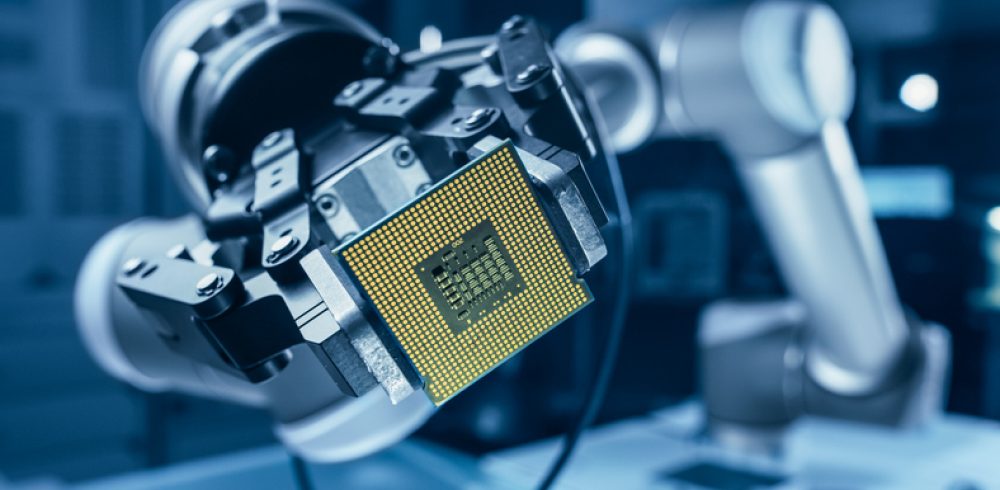

Cobots. Robots have been used in manufacturing for a while now, designed to work independently. However, new collaborative robots, or ‘cobots’, can work safely alongside humans. They perform tasks such as picking and packing, welding, assembly and even operating machines. They improve productivity by taking over repetitive, physically demanding and hazardous tasks, allowing human workers to focus on higher-skilled activities.

Augmented and Virtual Reality. These technologies can provide immersive environments for training workers or designing factory layouts without disrupting operations. They bridge the digital and physical worlds, enhancing productivity and safety. When used for training workers on hazardous materials or dangerous heavy industrial equipment, for example, virtual training can provide workers with a safer learning environment while still giving them a sense of hands-on training.

The Challenges to Overcome

While the potential of smart manufacturing is immense, the path forward is complex. It requires a workforce skilled in data science, AI, robotics and digital systems. Yet there is a widening skills gap and labor shortage today. Effective smart manufacturing requires the workflow and manufacturing expertise of an aging workforce, combined with those skilled in these new technologies. Finding this mix can be challenging, so companies must invest in reskilling and upskilling their workforce to ensure successful adoption and operation of new technologies.

Additionally, adopting smart manufacturing technologies involves significant upfront investments in hardware, software, and employee training. Small and medium-sized enterprises (SMEs) often struggle to afford these costs, creating a divide between large corporations and smaller manufacturers. Further, many manufacturers rely on decades-old legacy machines and systems that may not be compatible with modern technologies. Integrating smart systems with these legacy systems can be technically challenging and require customized solutions or complete system overhauls.

And then there is the issue of cultural resistance to change, especially when workers feel threatened by robots, AI and digital tools replacing their capabilities. Change management and clear communication are essential to create a culture that embraces innovation and digital transformation.

Succeeding as a manufacturer today requires embracing the tools, technologies and processes of the smart factory and adapting to the rapid pace of technological change. Yet despite a digitally forward corporate mindset, we also must keep in mind the essential role humans will continue to play in ensuring the safe, productive and effective use of advanced technologies, which will support but never supplant the ingenuity and expertise of people.

# # # #

As CEO of ETQ, Vick Vaishnavi is responsible for leading the overall business strategy and operations of ETQ. As a seasoned business and technology leader, Vick has extensive experience guiding software and other technology firms to industry leadership and business growth.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News